Precision That Protects Prints: Why the screen tension meter as-120n Is the Tool Your Shop Needs

The screen tension meter as-120n is more than a tool; it’s an insurance policy for quality. It turns subjective judgment into objective data, speeds setup, and reduces scrap. For any shop serious about consistent prints and tighter process control,

When quality matters, small differences in screen tension become big differences in print results. The screen tension meter as-120n is designed for shops, factories, and labs that demand consistent, repeatable tension measurements across polyester, nylon, and metal meshes. Whether you’re producing fine halftones for textile printing or tight registration for PCB stencils, controlling tension is the foundation of predictable printing. Read on to discover why this instrument belongs on every serious screen and stencil bench.

Make every screen predictable

A good screen starts with even tension across the mesh. Without precise measurement, one operator’s “feels right” can’t match another’s. The screen tension meter as-120n removes subjectivity by providing a digital readout with clear units and reliable repeatability. Instead of guessing, technicians get objective, numeric feedback that can be logged and trended — which means fewer rejects and less rework.

Core features that matter to real users

This device focuses on practical features operators actually use on the production floor:

-

Digital LCD readout for clear, instant readings and reduced human-reading error.

-

Unit conversion between N/cm and kg/cm for shops that use different standards or reports.

-

Fine resolution (0.1) so slight tension differences are visible and actionable.

-

Measuring range suited to most mesh types used in screen and stencil work (industry typical ranges). Alibabainstrumentstrade.com

These features let you measure and compare quickly — no guesswork, no second-guessing.

Real specs you can bank on

For teams that need numbers on paper, the screen tension meter as-120n commonly lists a measuring range around 7–40 N/cm, display resolution of 0.1, and supports standard power options like AAA batteries. Many suppliers also note optional data output (USB, RS-232 or Bluetooth) for logging to a PC or quality-control system — a feature that turns single measurements into usable production data. Alibabainstrumentstrade.com

What that means on the job

Imagine calibrating 20 screens for a four-color run. With manual methods you might waste 20–30 minutes per screen and still end up with uneven tension. With the screen tension meter as-120n, you can:

-

measure in seconds,

-

adjust tension to target values, and

-

confirm every panel meets the same standard.

The result is faster setup, better color consistency, and fewer callbacks.

Built for field and bench use

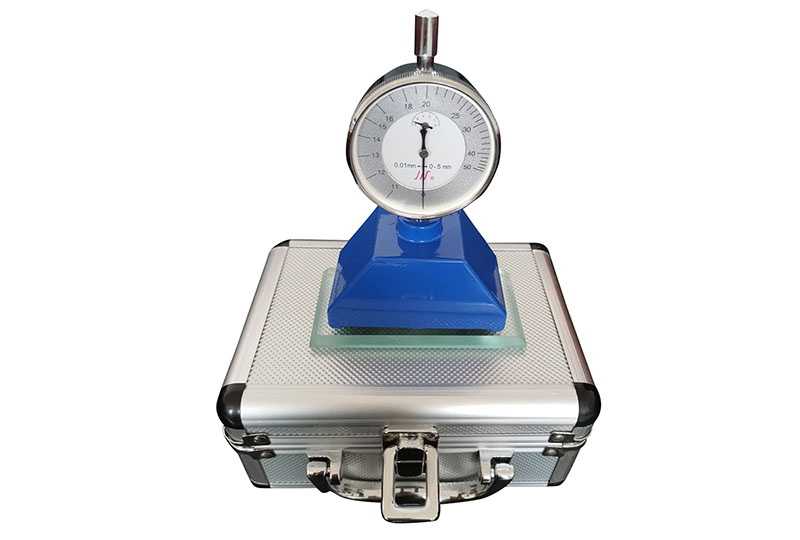

Durability matters in a production environment. The screen tension meter as-120n is compact and portable, so it travels from the stencil shop to the press room. It’s light enough to use handheld but robust enough for repeated daily use. Many suppliers provide a simple protective case and batteries so the tool is ready out of the box. 亚马逊eBay

Integration into quality systems

If you track incoming material and final output, the screen tension meter as-120n can be a datapoint in your quality system. With optional data output, recorded readings can be stored in spreadsheets or QC software to:

-

prove process capability,

-

identify tension drift over time, and

-

correlate tension changes with print defects.

That capability transforms a handheld meter into a component of continuous improvement.

Use cases — from textiles to electronics

This instrument isn’t single-purpose. Typical applications include:

-

textile screens where mesh tension affects dot gain and color density,

-

PCB stencil tensioning where registration is critical for fine-pitch solder paste,

-

specialty printing (ceramics, decals, glass) where consistent mesh performance ensures uniform deposits.

If your process depends on repeatable ink deposit or registration, the screen tension meter as-120n helps make your output consistent.

Practical advantages over subjective methods

Many shops still use manual “feeling” methods, or mechanical tensiometers that require more setup. Compared to those:

-

the screen tension meter as-120n reduces operator-to-operator variability,

-

it speeds measurement and allows quick corrections,

-

it lowers the training time required for junior staff.

Those benefits translate directly to lower waste and higher throughput.

Buying guidance: what to check before you purchase

When selecting a unit, confirm:

-

The measuring range matches the meshes you commonly use (typical: 7–40 N/cm listed by several vendors). Alibaba

-

Whether you need data output (USB/RS-232/Bluetooth) for logging or SPC. instrumentstrade.com

-

Battery type and expected life — AAA batteries are common and easy to source. eBay

-

What’s included (case, calibration certificate, cables) so you get a ready-to-use package.

Price and availability (what to expect)

This model is sold through multiple channels — direct suppliers, marketplaces, and specialized distributors — and price will vary with warranty, included accessories, and shipping. Checking multiple suppliers is standard practice; be mindful of after-sale support and calibration services when comparing offers. Representative listings show availability across major industrial suppliers and marketplaces. 亚马逊Alibaba

Quick comparison: AS-120N vs. generic handheld meters

In head-to-head terms, the screen tension meter as-120n generally competes well on:

-

accuracy and resolution, which improves defect detection;

-

feature set (unit conversion, optional data output);

-

ease of use (digital display vs. dial or analog).

If your shop depends on repeatable prints, the incremental cost of a reliable digital meter typically pays back quickly through reduced rework.

Real-world testimonial-style scenario

“A medium-size textile shop I worked with cut setup time by 30% after standardizing on the screen tension meter as-120n. The team could hit target tensions consistently, and our reject rate dropped because registration stayed stable across long runs.” — Production Manager, Specialty Printing

How to get the most from the instrument

To extract maximum value:

-

Set a tension target for each mesh type and document it.

-

Train at least two operators on measurement technique and logging.

-

Make tension checks part of pre-run setup and shift checks.

-

Use exported data to review trends monthly.

These practices convert single readings into process control.

Final thought — invest once, reduce waste forever

The screen tension meter as-120n is more than a tool; it’s an insurance policy for quality. It turns subjective judgment into objective data, speeds setup, and reduces scrap. For any shop serious about consistent prints and tighter process control, it’s a small investment that stabilizes output and protects margins.

If you want a hands-on comparison or a checklist for procurement and validation, I can provide a one-page technical checklist next — including items to ask vendors and a short operator training script to get your team up to speed.

Tension MeterPre:Surface Tension Meter Price: Choosing the Right Balance Between Cost and Capability

Next:Precision in Every Stroke: The Professional’s Guide to Choosing a stainless steel ink knife

Tags: