How to Calibrate Tension Meter — A Practical Guide and Why Proper Calibration Matters

Knowing how to calibrate tension meter is a core skill for anyone who relies on tension as a process control variable. Proper calibration protects quality, reduces downtime, and gives you the confidence that the numbers you read are meaningful. Use the si

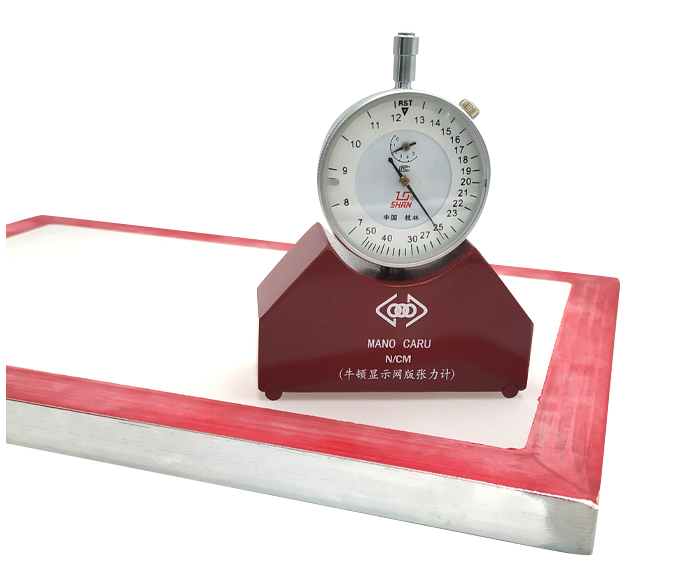

If you depend on tension meters to control processes—whether in textile stretching, screen printing, belt tensioning, or SMT stencil work—knowing how to calibrate tension meter is essential. Calibration turns a tool from a convenient gauge into a trusted instrument. This guide walks you through practical calibration steps, explains when and why to calibrate, and shows how a proper calibration practice protects your output quality and reduces waste.

Why calibration matters

A tension meter only helps when its readings are accurate and repeatable. An uncalibrated meter can drift with use, environmental changes, or mechanical wear—leading to incorrect decisions: reworking screens, scrapping parts, or compromising product quality. Regular calibration:

-

Establishes a known relationship between the instrument reading and true tension.

-

Lets multiple operators get the same result, removing “it feels tight enough” guesswork.

-

Detects worn springs, sticky pivots, or other mechanical issues before they cause trouble.

Industry guidance and manuals show that instruments should be checked against reference conditions (for example, mounted on a flat calibration glass to verify zeroing and pointer travel) as part of a routine validation.abqindustrial.netcheckline.com

When to calibrate

A practical schedule depends on usage and risk:

-

For heavy daily production use: consider scheduled calibration every 3–6 months.

-

For moderate use: every 6–12 months may suffice.

-

After any mechanical shock, unexpected readings, or a repair, recheck immediately.

Calibration houses and calibration guides recommend periodic calibration—often every six months—as a sensible default for many tensiometers. Frequent calibration is especially important in regulated or tightly controlled production environments.EML Calibration

What you need before calibrating

Gather the basics:

-

The tension meter and its manual. Many meters include an “instrument check” procedure you should follow.

-

A stable, flat calibration surface such as a glass plate (many manuals specifically use a glass plate for zero-check).abqindustrial.net

-

If available, a calibrated reference fixture or dead-weight/force standard for multi-point checks (used by labs and advanced fixtures).imeko.org

-

A clean, temperature-stable workspace to reduce variability.

Step-by-step: a practical calibration/verification routine

Below is a field-friendly procedure that mirrors what many manufacturers and manuals recommend for routine verification and minor calibration.

Step 1 — Visual inspection

Check for damage, loose screws, or obvious contamination. Make sure moving parts move freely.

Step 2 — Zero check on a flat surface

Place the meter on a smooth calibration glass or similar flat surface. Press gently as the manual directs and observe pointer/digital zero behavior. Some meters should sweep a full turn and return to zero; others require an adjustable zero ring to align the pointer. If the unit fails this basic check, it needs service.abqindustrial.netScreenPrinting.com

Step 3 — Single-point functional check

Place the meter on a known reference or use a simple fixture that applies a known load (if available) and compare readings. If the meter reads within tolerance, it’s likely fine for routine use.

Step 4 — Multi-point calibration (recommended for lab-grade validation)

If you have access to a calibration fixture or lab service, verify the meter at several load points across its range (for example 7, 15, 30, 40, 50 N/cm). This step shows linearity—whether the meter reads proportionally at low, mid and high tensions. Research and calibration devices often use this exact procedure to characterize meter performance.imeko.org

Step 5 — Adjust or record

If your tension meter has an adjustable zero or calibration ring, use the manufacturer’s method to set zero, then re-check at a reference point. If adjustments can’t bring the meter into tolerance, it should be serviced or sent to a calibration lab.

Step 6 — Document and schedule

Log the date, readings, and any adjustments. A calibration record is essential for traceability and for spotting gradual drift over time.

Interpreting calibration results and tolerances

Not all meters promise laboratory accuracy. A user-level target might be ±1–3% of reading for many shop meters; lab-grade instruments often aim for ±0.5–1%. Consult your meter’s specification to decide whether the observed deviation is acceptable or not.

If readings are off by a consistent offset, a simple zero adjustment can sometimes correct the instrument. If errors are nonlinear (i.e., small error at low load but large at high load), internal wear or damage may be the cause—send it for professional recalibration.

Using a calibration fixture or lab service

For the most reliable results, use a calibration fixture or accredited lab:

-

A fixture applies known, traceable loads to the sensor and checks the instrument across multiple points. This is how ISO-traceable calibration certificates are generated.abqindustrial.netcheckline.com

-

Accredited labs will return a calibration certificate showing measured values, uncertainties, and pass/fail statements—valuable for quality systems and audits.

If you manage production where yields depend on precise tension control, investing in periodic lab calibration is often cost-effective.

Common pitfalls and how to avoid them

-

Skipping the zero check — always verify zero on a flat surface before any measurements. Many manuals explicitly call this out.abqindustrial.net

-

Calibrating in a noisy environment — temperature swings or vibration affect readings; choose a calm environment.

-

Assuming all meters behave the same — different technologies (mechanical dial vs. digital) have different drift behaviors and maintenance needs.

-

Ignoring operator technique — consistent placement and gentle tapping (if required by the model) are part of a repeatable measurement. Manuals and tutorials demonstrate these small but crucial handling details.YouTube

Practical value: what proper calibration saves you

-

Less waste: fewer scrapped screens, belts, or PCB print runs.

-

Faster troubleshooting: remove tension as a suspect quickly with confidence.

-

Better repeatability: multiple operators get the same result.

-

Audit readiness: calibration records and certificates show process control.

If your shop needs help: calibration services and calibration-ready instruments

Some manufacturers ship meters with factory calibration and offer optional ISO-traceable calibration certificates. If you lack an in-house fixture, consider:

-

Buying instruments that come factory-calibrated and offer return-for-calibration service.abqindustrial.net

-

Contracting a local calibration lab to perform multi-point checks and provide a certificate.

-

Purchasing a simple calibration block or fixture for routine checks and scheduling annual lab calibration for traceability.

Quick checklist: daily, monthly, and yearly calibration habits

-

Daily / per shift: Zero-check on glass; spot-check one or two reference screens.

-

Monthly: Run a short drift profile: check at low, mid, and high tension points if you have a fixture.

-

Annually (or 6-monthly for heavy use): Full lab calibration with certificate.

Following this cadence keeps your meters honest and your production predictable.

Final words — bringing it all together

Knowing how to calibrate tension meter is a core skill for anyone who relies on tension as a process control variable. Proper calibration protects quality, reduces downtime, and gives you the confidence that the numbers you read are meaningful. Use the simple field checks for daily assurance, and rely on multi-point, traceable calibration when precision and audits demand it.

Tension MeterPre:SMT Stencil Screen Tension Meter: Why Accurate Stencil Tension Makes Your SMT Prints Reliable

Next:Newman Screen Tension Meter: The Durable, Accurate Choice for Consistent Prints

Tags: