Screen printing mesh material how to choose?

Here you can buy high quality screen printing mesh. All the meshes ara available in a variety of widths and lengths.

screen printing mesh selection guide:Screen printing Like other printing processes, there are many parameters that need to be controlled in screen printing. Screen printing processes, though relatively simple, also require checking various parameters to ensure accurate printing results. From cloth, mesh, net frame to the screen tension and other parameters, these must be based on the needs of printed matter to determine.so,Screen printing mesh material how to choose?

nylon screen printing mesh

nylon screen printing mesh

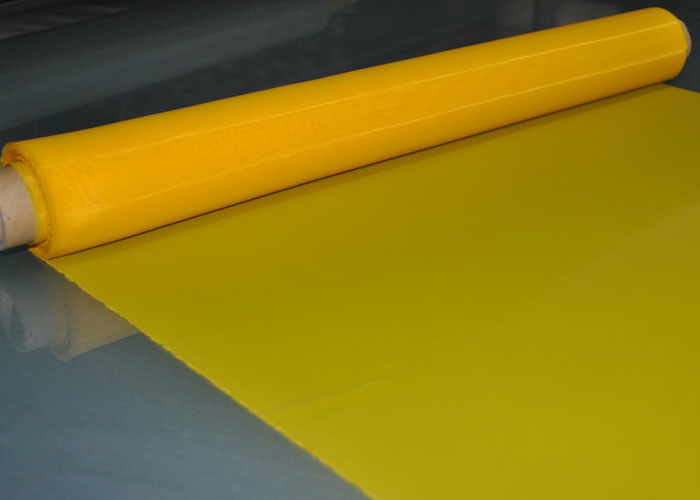

There are currently 2 kinds of mesh used in screen printing: nylon screen printing mesh and polyester screen printing mesh. Although polyester materials have been widely used around the world, screen printing companies are generally willing to use screen printing mesh made of nylon.

Polyester silk screen printing mesh has many unique advantages, such as anti-solution, high temperature, water and chemicals. In addition, his physical properties remain stable and scalability low when severe external pressure is applied. However, compared with nylon, polyester wear resistance is almost the same.

polyester screen printing mesh.

polyester screen printing mesh.

Because of its dimensional stability, polyester silk screen printing mesh is ideal for printing jobs that require high registration accuracy, such as printed circuit boards. The shortcomings of nylon screen printing mesh is stretched, tension retention ability is poor. After using for a period of time, the tension of the screen will be weakened, and make the screen slack, the printing accuracy drops, so the nylon screen printing mesh is not suitable for printed circuit boards and other fine products.

Screen printing is a wet printing process and must take moisture absorption into account. Nylon absorbs up to 5% moisture and loses 10% to 20% strength. It will be stretched 26 to 40% before breaking, while the polyester mesh stretches 19 to 23% before breaking.

Today, high-quality monofilament polyester has become the new darling of screen printing, it is round and smooth, with strong tensile strength and strength. In wet conditions, its strength will not be reduced. In fact, it absorbs up to 0.8% moisture. The nylon screen printing mesh cloth only in the irregular surface of the printing or three-dimensional products will be used.

After reading the above comparison, I believe you also know how to choose a silk screen printing mesh. If you still want to purchase a screen printing mesh or learn more about the introduction of screen printing mesh, please contact us and we will introduce more about Screen printing grid selection guide.screen printing mesh screen printing mesh material

Tags: