Screen Printing Mesh Material: Enhancing Precision and Quality in the Printing Process

In conclusion, selecting the right screen printing mesh material is essential for achieving high-quality prints that meet customer expectations. Whether you're working on bold designs for textiles or intricate prints for electronics, the choice of mes

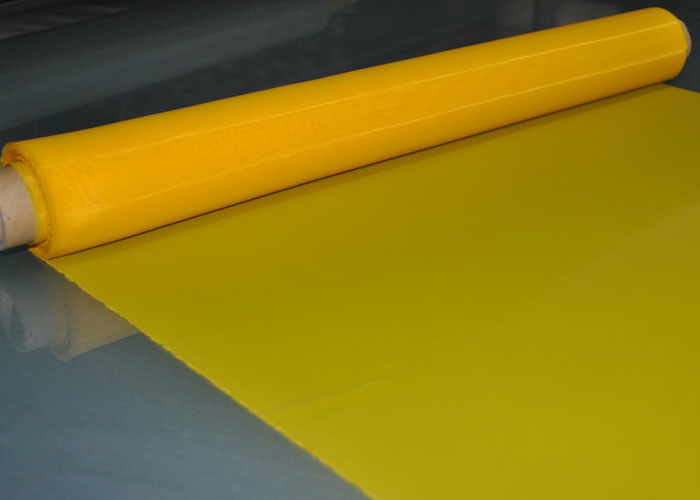

Screen printing has long been one of the most popular and versatile methods for transferring images onto surfaces such as textiles, ceramics, and electronics. At the core of the screen printing process lies the mesh material used in the screen itself. The type and quality of the mesh material significantly impact the precision, durability, and overall quality of the print. As the demand for more intricate and high-quality prints rises, it is crucial to understand the value of using premium screen printing mesh materials.

In this article, we will explore the advantages of high-quality screen printing mesh material, the variety of options available in the market, and why investing in the best screen mesh can enhance your printing outcomes.

The Importance of Mesh Material in Screen Printing

The mesh in screen printing serves as the medium through which ink is applied to the substrate. This makes it one of the most critical elements in the process, determining the accuracy and quality of the final product. The finer the mesh, the better it can handle detailed images and designs, but it also requires a finer ink consistency. On the other hand, coarser mesh materials are better suited for heavier ink deposits and larger designs.

When choosing mesh material, it is essential to consider factors like mesh count, thread thickness, and the material itself. These elements play a significant role in controlling the ink flow, the sharpness of the print, and the durability of the screen.

Common Mesh Materials for Screen Printing

Several materials are used to create screen printing mesh, each with its unique properties. The most popular options include:

-

Polyester Mesh: This is the most commonly used mesh material due to its durability, cost-effectiveness, and versatility. Polyester mesh is resistant to stretching, which ensures consistent results even after multiple uses. It also provides excellent dimensional stability, ensuring that the print remains sharp and precise.

-

Nylon Mesh: Known for its flexibility and durability, nylon mesh is often used in applications where the screen needs to withstand greater wear and tear. It is particularly useful in printing on uneven or curved surfaces. However, nylon mesh is more prone to stretching, which can affect print accuracy over time.

-

Stainless Steel Mesh: For applications requiring extreme precision, such as in the electronics industry, stainless steel mesh is the material of choice. It provides excellent dimensional stability and can withstand high tension without stretching. Stainless steel mesh also has a longer lifespan than synthetic meshes, but it comes at a higher cost.

-

Silk Mesh: Historically, silk was the original material used for screen printing mesh, but it has largely been replaced by synthetic materials due to cost and availability. However, silk is still used in specialty applications where the material’s unique properties are beneficial.

Mesh Count: The Key to Precision

Mesh count refers to the number of threads per inch in the screen. It is a crucial factor in determining the type of print you can achieve. Higher mesh counts are used for more detailed prints, while lower mesh counts are ideal for larger, more simplistic designs.

- Low Mesh Count (80-110 threads/inch): Best for printing on textiles where thicker ink deposits are required. It is commonly used for bold, solid designs with fewer details.

- Medium Mesh Count (156-230 threads/inch): Suitable for most standard printing applications, including fine details and text.

- High Mesh Count (305-420 threads/inch): Ideal for very fine detail work and precision prints, particularly on non-textile surfaces.

Selecting the correct mesh count ensures that the ink passes through the screen correctly, resulting in a clear, vibrant print.

Why Invest in High-Quality Screen Printing Mesh Material?

-

Improved Print Precision: High-quality mesh material provides better control over ink flow, allowing for sharper, more detailed prints. This is especially important for businesses producing intricate designs or printing on non-standard substrates.

-

Longer Screen Life: Cheap or low-quality mesh material may break or stretch after a few uses, leading to frequent replacements and higher costs in the long run. High-quality mesh is more durable and can withstand repeated use without losing its shape or print accuracy.

-

Enhanced Ink Efficiency: The right mesh material optimizes ink usage, reducing waste and ensuring that every drop of ink is applied evenly across the print. This is particularly beneficial for businesses looking to cut costs and increase productivity.

-

Versatility Across Substrates: High-quality mesh material works well across a variety of surfaces, including fabric, paper, plastic, and glass. This versatility allows businesses to expand their range of products and services without needing to invest in multiple types of screens.

-

Increased Production Speed: Quality mesh material is more consistent in its performance, allowing for faster production times without compromising on the quality of the print. This can be a significant advantage for businesses operating in high-demand environments.

Optimizing Your Business with Screen Printing Mesh

For businesses involved in screen printing, whether in textiles, advertising, or electronics, the choice of mesh material can make or break the final product. Investing in high-quality mesh ensures that every print is sharp, vibrant, and durable, which translates into satisfied customers and repeat business.

Additionally, premium mesh materials often come with better customer support and warranties, offering peace of mind to businesses that rely on consistent, high-volume production.

Conclusion

In conclusion, selecting the right screen printing mesh material is essential for achieving high-quality prints that meet customer expectations. Whether you're working on bold designs for textiles or intricate prints for electronics, the choice of mesh material will directly impact the outcome. Polyester, nylon, stainless steel, and even silk each have their place in the screen printing world, but the key to success lies in understanding the needs of your project and investing in a mesh material that delivers precision, durability, and versatility.

By focusing on the quality of your screen printing mesh, you can enhance your business's production capabilities, reduce waste, and ensure that every print is a success. Investing in the best materials may seem costly upfront, but the long-term benefits far outweigh the initial expense.

Pre:Ultimate Guide to Screen Printing Mesh: Choosing the Right Mesh for Your Needs

Next:The Complete Guide to Screen Printing Squeegees: Blades, Handles, Prices, and Types

Tags: