How to Use Screen Tension Meter: Unlock Precision, Consistency, and Print Quality

How to use screen tension meter isn't just a how-to—it’s a discipline. It’s the heartbeat of every crisp detail, every precise layer, every repeatable job. Tension isn’t optional; it’s foundational. Learn it, use it, and watch your prints el

If precision, repeatability, and quality matter to your screen printing, mastering how to use screen tension meter is a game-changer. It’s not merely shop talk—it’s how pro shops stay sharp from start to finish.

Why Even Tension Makes or Breaks Your Print

When your mesh is under the right tension, each stroke of the squeegee translates into crisp, detail-filled prints. Loose mesh yields smudged, soft designs. Too tight? It risks mesh distortion or damage. Knowing how to use screen tension meter let’s you control this balance precisely, so prints consistently sing with clarity and layers stay registered.

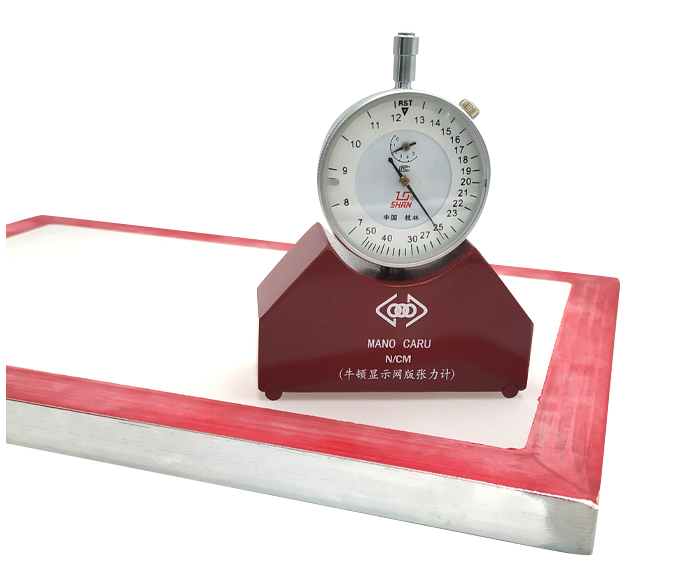

The Role of the Screen Tension Meter

A standard screen tension meter reads tension in Newtons per centimeter (N/cm). To use it effectively:

-

Place the meter on the mesh—usually at the center.

-

Tap the top gently—this overcomes mechanical friction and boosts consistency abqindustrial.net.

-

Read the value directly from the display or dial.

-

Rotate the screen 90° to measure both warp and weft tension, ensuring uniform stretch across directions printphase.com.

That’s your tension realized—not guessed.

Step-by-Step: Mastering “How to Use Screen Tension Meter”

Step 1: Prepare the Screen

Ensure mesh is clean and dry. Eliminating residue helps accuracy and repeatability.

Step 2: Position the Meter Mid-Screen

Start in the center of the print side. That gives you the most relevant baseline tension printphase.com.

Step 3: Light Tapping Technique

A few pulses to the mesh help settle the meter’s mechanism—essential for dependable readings abqindustrial.net.

Step 4: Apply Even, Gentle Pressure

Hold the meter squarely, not tilted, and let its weight activate the sensor evenly.

Step 5: Rotate and Repeat

Spin the screen to measure across both axes. Consistency here means better print control.

Step 6: Interpret the Reading

Target around 25–35 N/cm for most mesh counts—but adjust based on your mesh type or fabric demands First Trim.

Step 7: Adjust Tension If Needed

Too loose? Retension or re-stretch. Too tight? Slightly relax. Aim for consistency over power.

Step 8: Repeat Over Time

Tension drops with use. Measure routinely to maintain stability in every run.

How to Use Screen Tension Meter with Confidence

-

Repeatability: Tapping and careful placement ensure you get similar readings screen after screen.

-

Balanced Measurement: Measuring both directions avoids warping prints due to uneven tension.

-

Performance Flags: If prints shift or misregister, odds are tension is off—and your tension meter is your first detective.

Real Shop Benefits: What Pros Notice

One printing veteran shared that nearly all registration and blurring issues disappeared once they mastered how to use screen tension meter. Another emphasized how consistent tension creates a predictable exposure profile, leading to saved materials and faster setups. These aren’t cosmetic—it’s real, quality control made visible.

Selecting the Right Tension Meter

When shopping, keep in mind:

-

Accuracy: ±1 N/cm or better.

-

Ease: Digital or dial readouts.

-

Durability: Solid housing resists shop wear.

-

Maintenance: Tapping technique helps avoid friction-induced drift.

Final Thoughts

How to use screen tension meter isn't just a how-to—it’s a discipline. It’s the heartbeat of every crisp detail, every precise layer, every repeatable job. Tension isn’t optional; it’s foundational. Learn it, use it, and watch your prints elevate.

Tension Meter Screen Tension MeterNext:Screen Tension Meter Price: Making Sense of Your Investment for Professional Printing

Tags: