Screen Printing Tension Meter: The Tool That Turns Guesswork into Consistent Prints

A screen printing tension meter turns a subjective art into a controlled process. It’s simple to use, quick to adopt, and yields improvements across the whole print workflow—sharper prints, more reliable registration, less waste, and faster setups. Choose

If you’re serious about getting repeatable, high-quality screen prints, a screen printing tension meter is one of the smartest investments you can make. It’s a small tool with an outsized effect: proper tension delivers crisp halftones, reliable registration, and fewer wasted screens. This article explains why that happens, how to choose the right meter, and how to use it in real workflows so you see measurable gains quickly.

Why tension matters more than most people think

When mesh is uniformly taut, it reacts predictably under squeegee pressure. That stability is the reason small, controlled tweaks to tension can improve ink deposit, reduce ghosting, and keep multiple colors registered across long runs. Conversely, inconsistent tension causes subtle mesh flutter and stretch that translate into blurred edges and registration drift. Industry guides show this relationship clearly: maintaining the right tension band for your mesh is a core part of producing consistent work. ScreenPrinting.com

What a good screen printing tension meter actually tells you

A meter converts a tactile judgment into a reproducible number—usually expressed in Newtons per centimeter (N/cm). That number lets a shop:

-

Define target tension bands for each mesh count and job.

-

Train operators to hit the same target regardless of who stretches the frame.

-

Track drift over time and spot failing frames before they cause production problems.

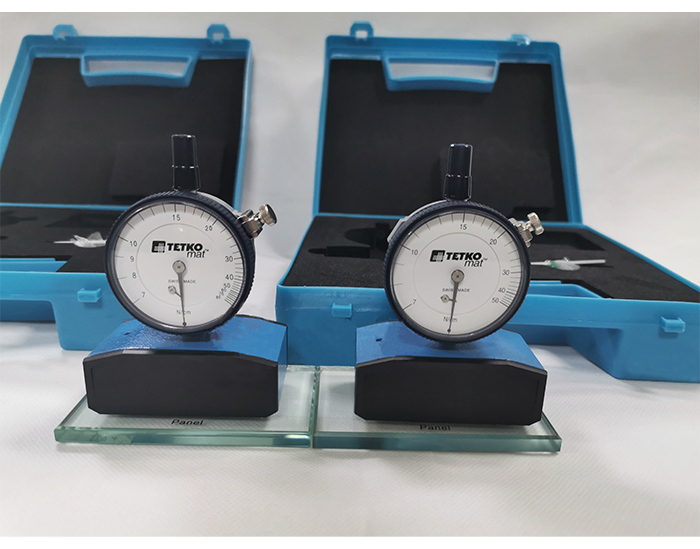

Several well-known meters on the market cover ranges suitable for textile and stencil work; examples include compact digital models and rugged mechanical gauges, each with tradeoffs between convenience and long-term durability. ScreenPrinting.comABQ Industrial

Choosing the right meter for your shop

Not all meters are created equal. When selecting a screen printing tension meter, consider these practical points:

-

Measurement range — Select a meter whose range comfortably covers the meshes you use. Common ranges on reputable meters include 6–50 N/cm and up to 130 N/cm for broader use. ABQ IndustrialScreenPrinting.com

-

Accuracy and calibration — If process control matters, prefer meters that ship with or offer traceable calibration certificates. Accuracy specs (for example ±1% full scale) matter for high-precision work. ScreenPrinting.com

-

Mechanical vs digital — Mechanical meters are battery-free and rugged; digital meters often offer easier reading and data export. Decide which convenience features you’ll actually use. gmgraphicssupply.com

-

Durability — Production environments are rough; choose housings and internals designed for shop use. A metal housing and protective case extend lifetime and reduce total cost of ownership. Shur-loc®

A mid-range, well-built meter is often the best value: accurate enough for most jobs, robust for daily use, and affordable to replace or recalibrate when needed.

How to use a screen printing tension meter — a practical routine

Adopting the meter into your routine is the single biggest multiplier for getting results. Here’s a concise, shop-tested routine:

-

Zero check before you start — Many meters include a small glass or flat surface for a quick zero/functional check. Do this at the start of each shift to confirm the instrument hasn’t been bumped. ScreenPrinting.com

-

Measure the right spot — Place the meter on the printable mesh area (not directly on the frame) and take readings in the center and a few edge points for larger frames. Center readings are the most repeatable baseline. DecoNetwork

-

Measure both axes — Rotate the screen 90° to check both warp and weft; many problems arise when tensions differ significantly between axes. ABQ Industrial

-

Record readings and act — Log the values with screen ID and date. If readings fall outside your target band, re-stretch or adjust clamps and recheck until values match the documented target. River City Supply

This routine takes minutes but prevents hours of troubleshooting later.

Real shop wins: what you can expect

Shops that adopt routine tension measurement commonly report:

-

Faster make-ready times because the big source of variability (tension) is controlled.

-

Fewer re-exposures and fewer wasted emulsions because stencils behave predictably.

-

Better multi-color registration since each screen responds similarly under squeegee stress.

Those practical improvements are why many shops say the meter pays for itself quickly. Community threads and demonstration videos reinforce that even inexpensive meters significantly improve outcomes versus guessing by feel. RedditYouTube

Common mistakes and how to avoid them

-

Measuring at the frame edge — readings there are distorted by the frame; sample the mesh area instead.

-

Skipping zero checks — many false readings come from bumped meters; a quick baseline check avoids that. stretchdevices.com

-

Using the wrong range — an undersized meter gives noisy readings; pick the right range for your mesh counts.

-

Not logging — without records you can’t spot slow drift or link tension to print outcomes.

Avoiding these mistakes makes the meter more than a diagnostic tool—it becomes a process control point.

Price vs. value: how much should you pay?

Price varies by brand and capability. Entry-level meters can be inexpensive and still vastly better than no meter; mid-range, calibrated meters from specialist suppliers are often the best choice for small shops, while lab-grade analyzers suit high-mix, high-precision operations. The right decision balances upfront cost, expected usage intensity, and the value of reduced waste and faster setup.

Many reputable meters include initial calibration and carry options for certified recalibration—useful if you run audits or need traceability. Shur-loc®ScreenPrinting.com

Training and adoption: make it stick

Tools deliver value only when people use them. Keep adoption simple:

-

Produce a one-page SOP that shows where to measure, target bands, and corrective actions.

-

Keep the meter near your stretcher or setup station—convenience drives use.

-

Run a short hands-on session with operators until readings are consistent.

-

Review tension logs monthly to detect trends.

Small process changes like this lock in large, ongoing benefits.

Final thought: small tool, big returns

A screen printing tension meter turns a subjective art into a controlled process. It’s simple to use, quick to adopt, and yields improvements across the whole print workflow—sharper prints, more reliable registration, less waste, and faster setups. Choose a meter that matches your shop’s needs, train your team, and make tension checks a routine step; you’ll see the difference the next time you run a job.

Tension MeterPre:Screen Tension Meter: Measure Once, Print Perfectly

Next:Surface Tension Meter Price: Choosing the Right Balance Between Cost and Capability

Tags: