Industrial Liquid Filter Bags for Reliable, High-Efficiency Process Filtration

Why industrial filtration performance starts with the right filter bag In industrial liquid processing, filtration is a foundational step that protects equipment, stabilizes product quality, and supports efficient production. Industrial liquid filter

Why industrial filtration performance starts with the right filter bag

In industrial liquid processing, filtration is a foundational step that protects equipment, stabilizes product quality, and supports efficient production. Industrial liquid filter bags play a critical role in this process by removing unwanted solids while maintaining steady flow and pressure. When filtration components are poorly selected, the result is often inconsistent output, increased downtime, and higher operating costs.

Reliable filtration begins with understanding how filter bags function within the broader system and why material, size, and construction matter.

What defines industrial liquid filter bags in demanding environments

Industrial applications place higher demands on filtration products than general-purpose systems. Industrial liquid filter bags are designed to withstand continuous operation, variable flow rates, and exposure to aggressive chemicals. Their construction emphasizes durability, dimensional stability, and consistent performance under pressure.

Unlike disposable consumer filters, these bags are engineered for repeatable results in complex process environments.

Common materials used in industrial filtration bags

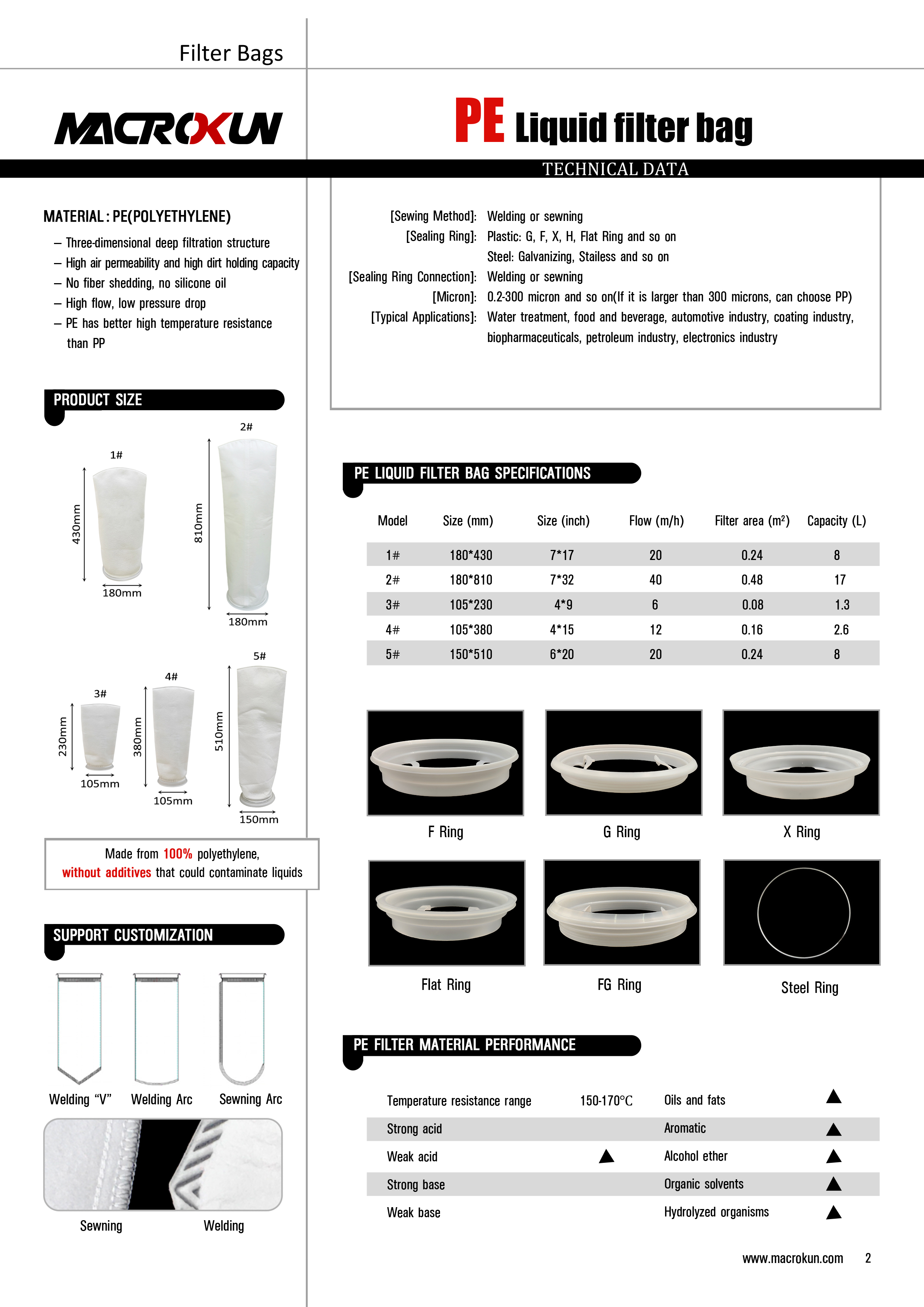

Most industrial liquid filter bags are manufactured using polypropylene, polyester, or nylon, each chosen for specific performance characteristics. Polypropylene offers excellent chemical resistance and cost efficiency. Polyester provides higher temperature tolerance and tensile strength. Nylon monofilament delivers precise surface filtration where particle size control is critical.

Selecting the appropriate material ensures compatibility with process fluids and extends service life.

Filtration mechanisms: depth versus surface capture

Filtration efficiency depends on how particles are captured. Depth-style filter bags trap contaminants throughout the thickness of the media, allowing high dirt-holding capacity. Surface-style bags collect particles on the surface, making them easier to clean and monitor.

Industrial liquid filter bags are available in both designs, enabling users to match filtration behavior to contamination type and process requirements.

Micron ratings and consistency in industrial use

Micron rating indicates the size of particles a filter bag can retain. In industrial systems, consistency is as important as the rating itself. Variations in pore size can lead to unpredictable filtration results.

High-quality industrial liquid filter bags maintain stable micron performance throughout their service life, ensuring reliable protection for downstream equipment and processes.

Bag size and its effect on flow and pressure

Bag dimensions directly affect flow capacity and pressure drop. Larger bags provide greater surface area, supporting higher flow rates and longer run times. Smaller bags are suitable for compact systems but may require more frequent replacement.

Properly selected industrial liquid filter bags help maintain steady pressure and reduce stress on pumps and piping.

Construction quality and seam strength

Seams are a critical point of failure in filtration bags. Reinforced stitching or welded seams improve durability and prevent rupture under load.

Well-constructed industrial liquid filter bags maintain structural integrity even during extended filtration cycles, reducing the risk of bypass or sudden failure.

Sealing methods and housing compatibility

Effective sealing ensures that all liquid passes through the filter media rather than around it. Industrial filter bags typically use plastic or metal rings to create a secure seal within the housing.

Correctly matched industrial liquid filter bags seat properly and maintain alignment, preserving filtration efficiency and preventing contamination bypass.

Typical industrial applications and use cases

Industrial liquid filter bags are widely used across multiple sectors. In water treatment, they remove sediment and suspended solids. In chemical processing, they protect sensitive reactions from contamination. In food and beverage production, they support clarification and product consistency.

Their versatility makes them a core component in many process filtration systems.

Flow stability and operational reliability

Stable flow is essential for efficient production. Sudden pressure increases caused by clogged filters can disrupt operations and damage equipment.

By selecting appropriate industrial liquid filter bags, operators achieve smoother flow behavior and predictable maintenance intervals.

Service life and replacement planning

Longer service life reduces labor requirements and downtime. Industrial filter bags designed for high dirt-holding capacity extend operating intervals between change-outs.

Consistent performance from industrial liquid filter bags simplifies maintenance planning and improves overall system reliability.

Cleanability and reuse considerations

In some applications, filter bags can be cleaned and reused, depending on contaminant type and operating conditions. Surface filtration bags are particularly suited for this approach.

Reusable industrial liquid filter bags help reduce waste and lower long-term filtration costs where reuse is feasible.

Quality control and production consistency

Manufacturing consistency ensures that each filter bag performs like the last. Tight control over materials, dimensions, and construction methods is essential.

Reliable industrial liquid filter bags are produced under standardized processes that deliver predictable results across multiple production batches.

Sampling and performance validation

Before full-scale implementation, testing filter bags under real operating conditions is strongly recommended. Sampling allows users to evaluate pressure drop, filtration efficiency, and service life.

Testing confirms that selected industrial liquid filter bags meet process requirements and reduces the risk of unexpected performance issues.

Cost efficiency and total operational value

While unit price is a consideration, total cost of ownership provides a clearer picture of value. Factors such as service life, labor, downtime, and disposal all contribute to overall cost.

High-performance industrial liquid filter bags often deliver better long-term value despite a higher initial investment.

Environmental impact and sustainability goals

Reducing waste and improving efficiency are priorities for many industrial operations. Longer-lasting filter bags generate less waste and reduce the frequency of disposal.

Thoughtful selection of industrial liquid filter bags supports both operational efficiency and environmental responsibility.

Common selection mistakes in industrial filtration

One common mistake is undersizing filter bags to reduce upfront cost, leading to rapid clogging. Another is choosing material without considering chemical compatibility.

Avoiding these issues requires a holistic understanding of how industrial liquid filter bags interact with the entire filtration system.

How to evaluate suppliers and product options

Evaluating filter bags involves reviewing material quality, construction standards, and production consistency. Suppliers that provide detailed specifications and technical support are better equipped to meet industrial demands.

Reliable industrial liquid filter bags come from sources that prioritize performance consistency and customer understanding.

Custom solutions for specialized systems

Some industrial systems require non-standard sizes or unique construction features. Customized filter bags ensure optimal fit and performance in these applications.

Custom industrial liquid filter bags are particularly valuable in legacy systems or highly specialized processes.

Building a long-term filtration strategy

Effective filtration planning looks beyond immediate needs. Anticipating changes in production volume, contamination load, or process fluids helps guide bag selection.

A long-term approach ensures that industrial liquid filter bags continue to perform as operations evolve.

Final thoughts on industrial liquid filtration reliability

Industrial filtration success depends on selecting components that perform consistently under real conditions. Filter bags are a critical part of that equation.

By choosing industrial liquid filter bags that match material, size, and performance requirements, organizations can achieve stable filtration, reduced maintenance, and reliable production outcomes.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Pre:Buy Liquid Filter Bag Solutions That Deliver Reliable Filtration and Long-Term Value

Next:String Wound Filter Cartridge: A Reliable Depth Filtration Solution for Industrial Water Treatment

Tags: