Buy Liquid Filter Bag Solutions That Deliver Reliable Filtration and Long-Term Value

Why purchasing the right filter bag matters more than price When industrial buyers decide to buy liquid filter bag products, the choice directly affects filtration efficiency, system stability, and operating costs. A filter bag is not just a consumabl

Why purchasing the right filter bag matters more than price

When industrial buyers decide to buy liquid filter bag products, the choice directly affects filtration efficiency, system stability, and operating costs. A filter bag is not just a consumable; it is a working component that influences flow rate, pressure balance, and product quality. Selecting the wrong bag often leads to premature clogging, inconsistent filtration, and unnecessary downtime.

Understanding what to look for before you buy ensures that filtration systems operate smoothly and consistently over time.

What professionals consider before they buy liquid filter bag products

Experienced operators rarely focus on price alone. They evaluate material compatibility, micron accuracy, construction quality, and service life. When buyers choose to buy liquid filter bag options based on these factors, they reduce the risk of system disruptions and unexpected maintenance.

Professional purchasing decisions are guided by performance consistency rather than short-term savings.

Material selection and its impact on filtration performance

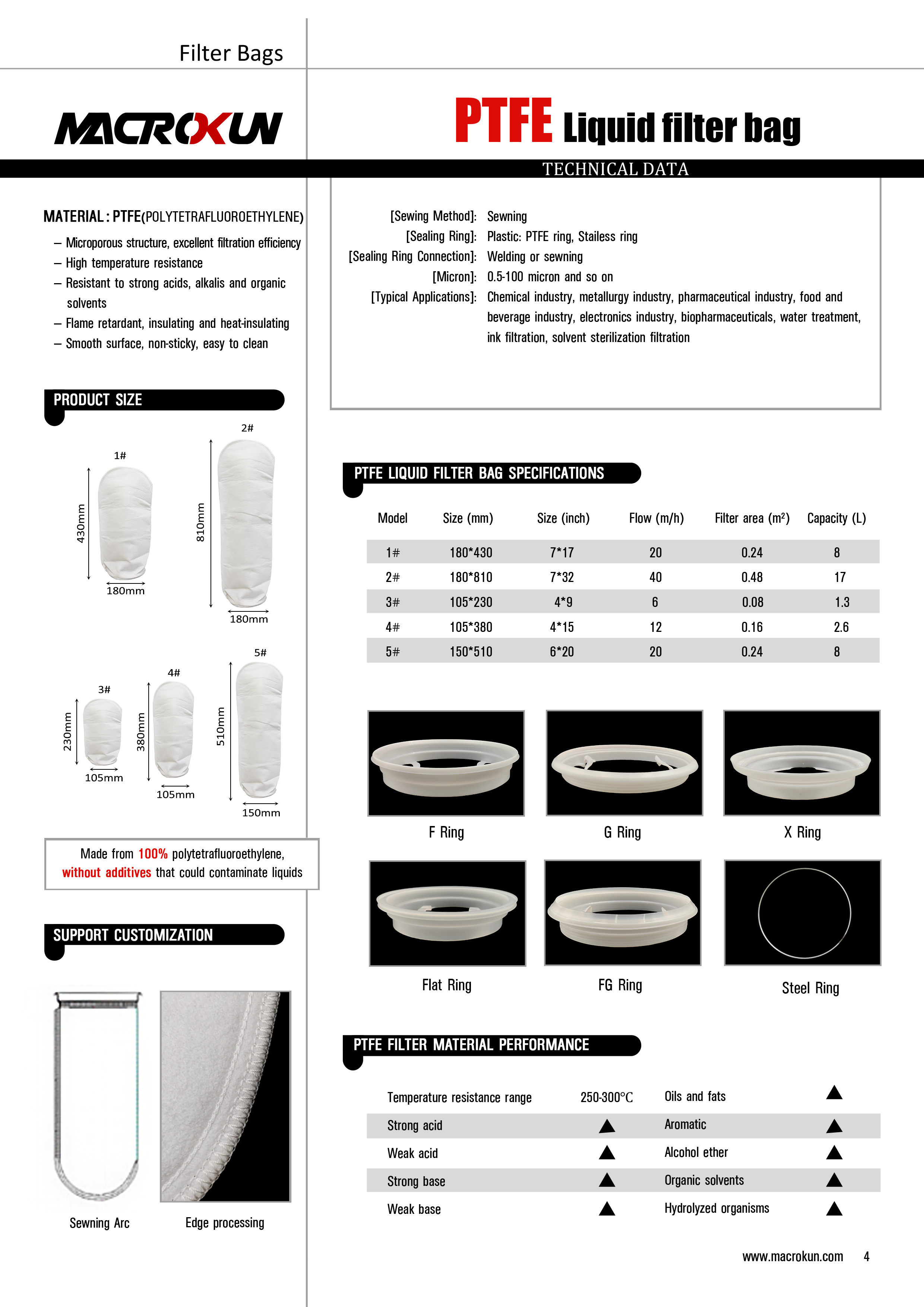

Filter bags are commonly produced from polypropylene, polyester, and nylon. Each material behaves differently under chemical exposure, temperature variation, and pressure.

When planning to buy liquid filter bag solutions, understanding material properties is essential. Polypropylene offers strong chemical resistance and cost efficiency. Polyester provides enhanced mechanical strength. Nylon monofilament delivers precise surface filtration for applications requiring easy cleaning.

Micron rating and real-world filtration accuracy

Micron rating defines the particle size captured by a filter bag, but consistency is just as important as the number itself. Poorly controlled micron distribution leads to unpredictable filtration results.

Buyers who buy liquid filter bag products with clearly defined micron performance achieve more stable contaminant removal and protect downstream equipment from damage caused by particle breakthrough.

Bag construction and durability under operating pressure

Construction quality determines how well a filter bag holds up during operation. Reinforced seams, uniform stitching, and proper welding prevent failures under pressure.

When operators buy liquid filter bag products with strong construction, they reduce the likelihood of bypass and avoid sudden process interruptions caused by torn or collapsed bags.

Sealing performance and housing compatibility

A filter bag must seal correctly within the housing to function effectively. Poor sealing allows unfiltered liquid to bypass the media, undermining the entire filtration process.

Those who buy liquid filter bag options designed to match standard housings benefit from reliable seating, consistent flow paths, and improved overall efficiency.

Understanding standard bag sizes and flow capacity

Bag size determines surface area and dirt-holding capacity. Larger bags typically support higher flow rates and longer service intervals, while smaller bags suit compact systems.

Before deciding to buy liquid filter bag products, buyers should evaluate flow requirements to ensure the selected size maintains stable pressure throughout the filtration cycle.

Application-specific considerations when purchasing

Different industries impose different demands on filtration systems. Water treatment applications emphasize continuous flow and durability. Chemical processing requires resistance to aggressive fluids. Food and beverage production prioritizes cleanliness and material integrity.

Knowing how to buy liquid filter bag products tailored to each application ensures reliable performance and compliance with process expectations.

Service life and replacement frequency

Service life directly affects operating costs. Bags that clog quickly increase labor requirements and disrupt production schedules.

Organizations that buy liquid filter bag solutions designed for extended use experience fewer change-outs and smoother daily operations, improving overall productivity.

Testing and validation before full-scale use

Trial testing is an important step in the purchasing process. Installing sample bags allows operators to observe pressure drop, flow stability, and contaminant capture under real conditions.

Those who buy liquid filter bag products only after validation reduce risk and build confidence in long-term filtration performance.

Cost evaluation beyond unit price

The lowest unit price does not always represent the best value. Total cost includes service life, maintenance effort, downtime, and disposal.

When decision-makers buy liquid filter bag options with longer lifespan and consistent performance, total operating expenses often decrease despite a higher initial cost.

Storage, handling, and operational convenience

Filter bags should be easy to store, handle, and install. Lightweight materials and standardized sizes simplify inventory management and reduce handling time.

Choosing to buy liquid filter bag products that integrate smoothly into existing maintenance routines saves time and minimizes operational complexity.

Environmental responsibility and waste reduction

Reducing waste is an increasing priority for industrial operations. Longer-lasting filter bags generate less disposal volume and support more sustainable practices.

Companies that buy liquid filter bag products with optimized service life contribute to environmental goals while maintaining effective filtration.

Common purchasing mistakes to avoid

A common mistake is selecting bags solely based on micron rating without considering flow or contaminant load. Another is undersizing to save cost, which often leads to rapid clogging.

Avoiding these mistakes requires understanding how a buy liquid filter bag decision affects the entire filtration system rather than focusing on isolated specifications.

How to compare suppliers effectively

Comparing suppliers involves more than reviewing catalogs. Buyers should assess material consistency, quality control practices, and willingness to provide technical support.

Organizations that buy liquid filter bag solutions from transparent and knowledgeable suppliers benefit from predictable quality and reliable supply continuity.

The importance of consistency across repeat orders

Repeatability is critical in industrial filtration. Replacement bags must perform the same as previous batches to avoid system recalibration.

When companies buy liquid filter bag products from consistent production sources, they maintain stable filtration performance across multiple production cycles.

Customization and non-standard requirements

Some systems require non-standard dimensions or specific construction features. In these cases, customization ensures proper fit and optimal performance.

Knowing when to buy liquid filter bag solutions with customized specifications helps address unique process challenges without compromising efficiency.

Long-term planning for filtration systems

Filtration decisions should align with long-term operational goals. Anticipating changes in flow, contamination levels, or production volume helps guide bag selection.

Strategic planning allows organizations to buy liquid filter bag products that remain effective as processes evolve over time.

Building confidence through informed purchasing

Confidence in filtration comes from understanding how each component functions within the system. Informed buyers make decisions based on performance data and operational needs.

When teams buy liquid filter bag solutions with a clear understanding of their requirements, filtration becomes a reliable support function rather than a recurring concern.

Final thoughts on making the right purchasing decision

Choosing the right filter bag is a balance between performance, durability, and cost efficiency. Thoughtful evaluation leads to stable filtration, reduced downtime, and consistent output quality.

By approaching the decision to buy liquid filter bag products with a focus on long-term value, organizations can achieve dependable filtration results that support efficient and reliable operations.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Pre:PP Liquid Filter Bag Solutions for Reliable, Cost-Effective Industrial Filtration

Next:Industrial Liquid Filter Bags for Reliable, High-Efficiency Process Filtration

Tags: