Achieve Ultra‑Fine Filtration with #2 Size, 0.5 Micron Polyester Felt Liquid Filter Bags

The #2 Size 0.5 Micron Liquid Filter Bags, Polyester Felt, Polypropylene Ring deliver the ultimate combination of ultra‑fine depth filtration, robust chemical compatibility, and seamless sealing—ideal for applications where absolute removal of sub‑visible

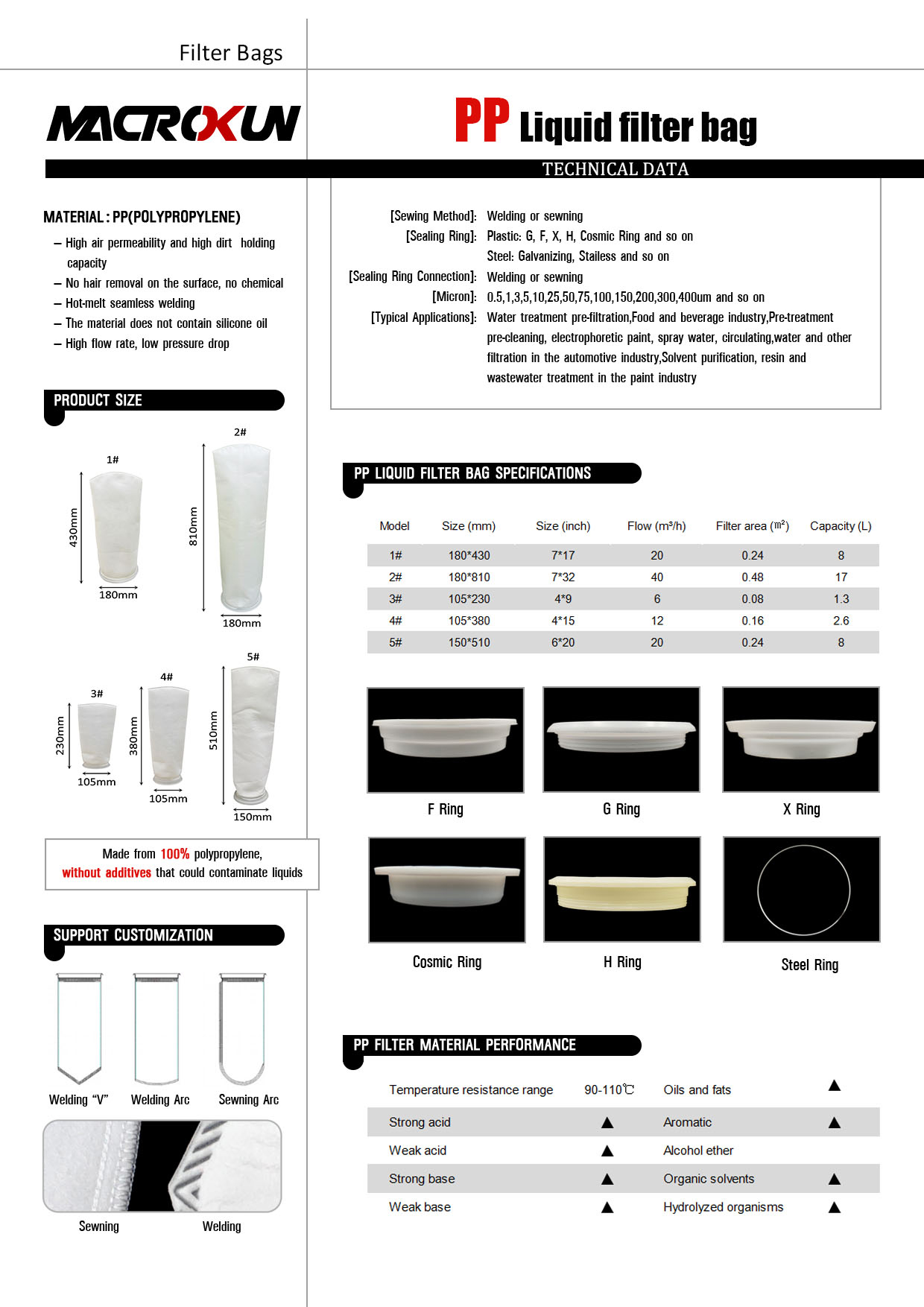

When your process demands removal of sub‑visible contaminants—down to half a micrometer—to protect sophisticated equipment, ensure product purity, or meet stringent regulatory standards, ordinary filters simply won’t suffice. Our #2 Size 0.5 Micron Liquid Filter Bags, crafted from high‑loft polyester felt and sealed with a polypropylene “F” flange ring, deliver absolute 0.5 µm depth filtration in standard 4″ × 10″ or 4″ × 20″ housings. From pharmaceutical intermediates and brewery bright tanks to semiconductor rinse loops and critical chemical streams, these filter bags provide unmatched clarity, durability, and chemical compatibility.

This comprehensive guide follows a proven structure—market overview, product fundamentals, key features, selection guidance, maintenance best practices, reasons to choose our offering, illustrative use cases, and actionable next steps—to help you deploy 0.5 µm filtration with confidence and efficiency.

Market Overview: The Rise of Sub‑Micron Filtration

Across industries, the need for ultra‑fine, reliable filtration is growing rapidly:

-

Protecting High‑Value Equipment

Turbomolecular pumps, precision valves, and ultra‑pure water loops in semiconductor fabs can be irreversibly damaged by particles larger than 0.5 µm. Removing these contaminants extends equipment life and prevents costly downtime. -

Ensuring Product Purity

In pharmaceuticals, biologics, and food & beverage, sub‑visible particulates can impact sterility, taste, and safety. Absolute 0.5 µm filters are the last line of defense before final sterile barriers. -

Regulatory & Quality Compliance

cGMP, FDA, and SEMI standards often require validated absolute‑rated depth filters to ensure removal of microorganisms and colloids larger than the rated size. -

Process Efficiency

By capturing fine haze and micro‑sediments early, you reduce fouling of downstream membrane cartridges and UV systems, cutting consumable costs and maintenance frequency. -

Versatile Applications

From wine and spirits polishing to critical chemical clarifications, 0.5 µm polyester felt bags serve as reliable polishing stages that adapt to a wide pH range and moderate temperatures.

These drivers underscore why many operations integrate absolute 0.5 µm polyester felt bags as a standard polishing element in their filter trains.

Product Fundamentals: Understanding #2 Size, 0.5 Micron Polyester Felt Bags

Our #2 Size 0.5 Micron Liquid Filter Bags combine depth‑filtration media, precise manufacturing, and robust sealing for consistent sub‑micron performance:

-

Media: Multi‑layer, high‑loft polyester felt engineered for absolute 0.5 µm retention (≥99.9% capture of particles ≥0.5 µm) with superior dirt‑holding capacity.

-

Bag Size: “Size 2” refers to a nominal 4″ internal diameter and choice of 10″ or 20″ length to fit all standard Size 2 housings (single, dual, or multi‑bag configurations).

-

Ring Style: Polypropylene “F” flange ring molded for precise fit on housing support ledges, providing leak‑free operation in pH 2–12 fluids up to 180 °F.

-

Construction: Ultrasonic or heat‑welded seams eliminate stitch holes, preventing fiber migration and stitch‑leakage while supporting up to 75 psi differential.

Fluid enters the bag’s exterior surface, travels through the felt depth (trapping contaminants throughout), and flows out the interior, delivering ultra‑clear, contaminant‑free fluid for downstream critical stages.

Key Features of Our 0.5 Micron Polyester Felt Bags

When evaluating sub‑micron filter bags, these features determine performance and value:

1. Absolute 0.5 Micron Retention

-

Depth‑Filtration Efficiency: Multi‑layer felt matrix provides uniform capture throughout media depth rather than surface sieving alone.

-

Validated Performance: Each bag is tested to confirm ≥99.9% retention of particles ≥0.5 µm under standardized flow and pressure conditions.

2. High‑Loft Polyester Felt Media

-

Dirt‑Holding Capacity: Thick, open structure traps large volumes of fine particles before ΔP rise.

-

Thermal & Chemical Tolerance: Stable to 180 °F, resistant to most aqueous streams, mild acids, and alkalis.

3. Polypropylene “F” Flange Ring

-

Secure, Bypass‑Free Seal: Rigid flange seats flush against housing ledge, ensuring all fluid traverses the media.

-

Chemical Inertness: Compatible with pH 2–12, preserving ring integrity and preventing contamination.

4. Welded Seam Construction

-

Zero Stitch‑Hole Bypass: Ultrasonic welding or heat fusion bonds layers seamlessly, preventing any leak paths.

-

Structural Strength: Seam supports full differential pressure rating, even in high‑flow scenarios.

5. Flexible Size & Length Options

-

10″ & 20″ Lengths: Choose shorter bags for lower flow or compact housings; longer bags double service life in higher‑flow systems.

-

Multi‑Bag Housing Compatibility: Ideal for both single‑bag and multi‑bag assemblies to meet varied throughput requirements.

6. Low Pressure Drop

-

Optimized Fiber Density: Balances fine retention with minimal initial ΔP, ensuring pump energy efficiency and stable operation.

These attributes make our 0.5 µm felt bags a reliable choice for the final polishing or pre‑sterilization stage in critical fluid streams.

Selecting the Right Filter Bag for Your Application

To ensure optimal performance, match bag characteristics to your process:

A. Determine Filtration Stage

-

Final Polishing/Pre‑Sterile: Use absolute 0.5 µm bags upstream of membrane cartridges, UV sterilizers, or sterile barriers.

-

Pre‑Filtration: If solids load is minimal, 0.5 µm may serve as the first stage to protect downstream elements.

B. Establish Flow & Housing Requirements

-

Flow Rate: 10″ Size 2 bags handle ~10–15 GPM; 20″ handle ~20–30 GPM per bag at low ΔP. For higher flows, use multi‑bag housings.

-

Pressure Constraints: Verify your system pump can deliver sufficient backpressure—bags rated to 75 psi differential.

C. Validate Chemical Compatibility

-

Process Fluid: Confirm polyester felt and polypropylene ring are compatible with your fluid chemistry, temperature, and cleaning agents.

-

Sanitary Standards: For food, beverage, or pharmaceutical, ensure materials meet CFR‑21, FDA, or USP Class VI requirements.

D. Define Maintenance & Changeout Strategy

-

Disposable Use: Single‑use eliminates cleaning validation in sterile or controlled environments.

-

Reusable Potential: If permitted, gentle backflush and chemical sanitization can extend bag life—validate cleaning protocols for PTFE or other higher‑temp resists.

E. Confirm Housing Seal & Support

-

O‑Ring/Gasket Matching: Ensure housing support rings and gaskets align with F‑flange design to prevent bypass.

-

Support Cages: For high flows or frequent changeouts, confirm internal cages fit and support the bag without collapse.

By systematically evaluating these factors, you’ll select the perfect 0.5 µm filter bag configuration for your critical process needs.

Maintenance Best Practices

Implementing proper maintenance routines preserves filter performance and avoids unplanned downtime:

1. Differential Pressure Monitoring

-

Gauges: Install ΔP gauges upstream and downstream to detect media loading.

-

Changeout Threshold: Replace bags when ΔP approaches 20–25 psi to prevent bypass or media damage.

2. Safe Bag Changeout

-

Handle & PPE: Use gloves and bag handles or changeout tools to protect operators and maintain cleanliness.

-

Cleanroom Protocols: Adhere to aseptic techniques in sterile environments to avoid contamination.

3. Disposal or Cleaning

-

Disposable Protocol: Discard used bags per your facility’s waste procedures; consider autoclaving for biological loads if required.

-

Reuse Considerations: If cleaning, employ recommended solvents or cleaning agents, followed by thorough rinsing and sanitization. Confirm felt integrity before reuse.

4. Housing & Gasket Care

-

Interior Cleaning: Wipe housing walls and support elements during each change to remove residual particles.

-

Seal Inspection: Replace gaskets and O‑rings showing wear to maintain leak‑free operation.

5. Record Keeping & Performance Tracking

-

Service Logs: Document installation date, ΔP at removal, and total volume processed to refine changeout intervals.

-

Filtrate Testing: Periodically test effluent turbidity or particle counts to verify absolute retention.

Consistent maintenance ensures reliable, repeatable filtration results and extends component life.

Why Choose Our 0.5 Micron Starter Pack?

Our #2 Size 0.5 Micron Polyester Felt Liquid Filter Bags stand out because:

Absolute Retention Guarantee

-

≥99.9% Efficiency: Certified to capture all particles ≥0.5 µm, protecting downstream critical stages.

Premium Depth‑Filtration Media

-

High‑Loft Polyester Felt: Engineered for uniform fiber distribution, maximum dirt‑holding, and minimal shedding.

Robust Polypropylene Rings

-

Chemical Compatibility: Suitable for aqueous, mildly acidic, and mildly alkaline streams at up to 180 °F.

-

Precision Fit: F‑flange design ensures complete bypass‑free sealing in all Size 2 housings.

Seamless Construction

-

Ultrasonic or Heat Fusion Seams: Eliminate stitch holes, preventing particle bypass and fiber migration.

Flexible Size & Length Options

-

10″ & 20″ Bags: Adapt to various flow rates and housing dimensions for maximum operational flexibility.

Rigorous Quality Control

-

Batch Testing: Each lot undergoes retention, flow, and dimensional verification to meet ISO and industry standards.

By integrating our 0.5 µm felt bags into your filter train, you secure uncompromised fluid purity, protect high‑value assets, and meet stringent regulatory requirements.

Illustrative Use Cases

Use Case 1: Semiconductor Ultrapure Water

A chip fab installed 0.5 µm polyester felt bags ahead of final DI polishing. The absolute retention prevented particulate breakthrough to UV and membrane stages, boosting yield and reducing wafer defects.

Use Case 2: Biotech Fermentation Harvest

A biotech firm clarified cell culture supernatant with 0.5 µm bags prior to sterile filtration. The deep‑filtration step preserved protein product integrity and extended life of final sterile cartridges.

Use Case 3: Beverage Micro‑Polishing

A craft brewery polished bright beer with 0.5 µm felt bags before sterile bottling. Customers reported improved clarity and shelf stability, and the disposable bags simplified changeover during production runs.

Use Case 4: Critical Chemical Reactor Feed

An electronics chemicals plant filtered etchant streams with 0.5 µm bags to remove colloidal metal oxides. This pre‑clarification step protected precision spray nozzles, reducing maintenance by 50%.

These scenarios demonstrate the transformative impact of absolute‑rated 0.5 µm filtration in high‑stakes processes.

Summary and Next Steps

The #2 Size 0.5 Micron Liquid Filter Bags, Polyester Felt, Polypropylene Ring deliver the ultimate combination of ultra‑fine depth filtration, robust chemical compatibility, and seamless sealing—ideal for applications where absolute removal of sub‑visible particulates is non‑negotiable.

Next Steps:

-

Define Your Filtration Challenge: Specify flow rate, fluid chemistry, temperature, and required clarity.

-

Select Bag Length & Housing: Choose 10″ or 20″ Size 2 bags to match your system’s throughput and vessel dimensions.

-

Implement ΔP Monitoring: Install pressure gauges to track media loading and schedule changeouts.

-

Establish Changeout Protocols: Train operators on aseptic or safe handling techniques and disposal or cleaning procedures.

-

Measure Performance Gains: Monitor downstream equipment uptime, product purity metrics, and consumable costs to validate the impact of 0.5 µm filtration.

By incorporating these premium filter bags into your process, you’ll achieve unparalleled fluid clarity, protect critical assets, and maintain compliance with the most demanding industry standards—ensuring smooth, reliable operations day after day.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Next:Achieve Precision Filtration with #2 Size, 1 Micron Polyester Felt Liquid Filter Bags

Tags: