Versatile Bulk Filtration with #2 Size Filter Bag Starter Pack, High Micron, Polyester Felt, Polypropylene Ring

The #2 Size Filter Bag Starter Pack, High Micron, Polyester Felt, Polypropylene Ring is your all‑in‑one solution for bulk solids control in Size 2 housings. Its mix of 50 µm to 300 µm bags, robust media, and slip‑proof collars ensures you’re ready for any

When your process demands rapid removal of large particulates—such as rust flakes, weld spatter, sediment, or coarse debris—fine filters clog too quickly and disrupt operations. A #2 Size Filter Bag Starter Pack, High Micron, Polyester Felt, Polypropylene Ring delivers an immediate solution: a curated set of coarse‑micron, durable filter bags sized for standard 4″ × 10″ and 4″ × 20″ housings. Whether you’re commissioning a new system, combating heavy solids loads, or stocking spares for emergency change‑outs, this starter pack equips you to maintain flow, protect downstream equipment, and simplify inventory management.

This guide follows a proven structure—market overview, product fundamentals, key features, selection guidance, maintenance best practices, reasons to choose our pack, illustrative use cases, and actionable next steps—to help you deploy high‑micron filtration with confidence.

Market Overview: The Importance of High‑Micron Pre‑Filtration

Across industries, coarse particulate control via high‑micron filtration is a critical first‑stage strategy:

-

Protecting Equipment from Abrasion

Large solids in cooling water, washdown return lines, or chemical slurries rapidly erode pumps, valves, and nozzles. Capturing particles ≥50 µm prevents damage and extends asset life. -

Maximizing Downstream Filter Life

Bulk solids removal at coarse micron ratings significantly reduces the loading on finer cartridges or membranes, cutting consumable costs and maintenance labor. -

Maintaining High Flow Rates

Processes handling >100 GPM require filters that won’t constrain flow. High‑micron bags, with their open media structure, sustain minimal pressure drop even under heavy solids loads. -

Simplified Changeouts

Larger pore sizes allow quick surface cleaning or replacement, minimizing downtime during bag swaps in demanding production environments. -

Inventory Efficiency

Starter packs that bundle the most common high‑micron ratings help facilities reduce SKU counts and respond rapidly to varying process demands.

These trends underscore why high‑micron starter packs have become a best practice for bulk solids management.

Product Fundamentals: What’s in the #2 Size High‑Micron Starter Pack

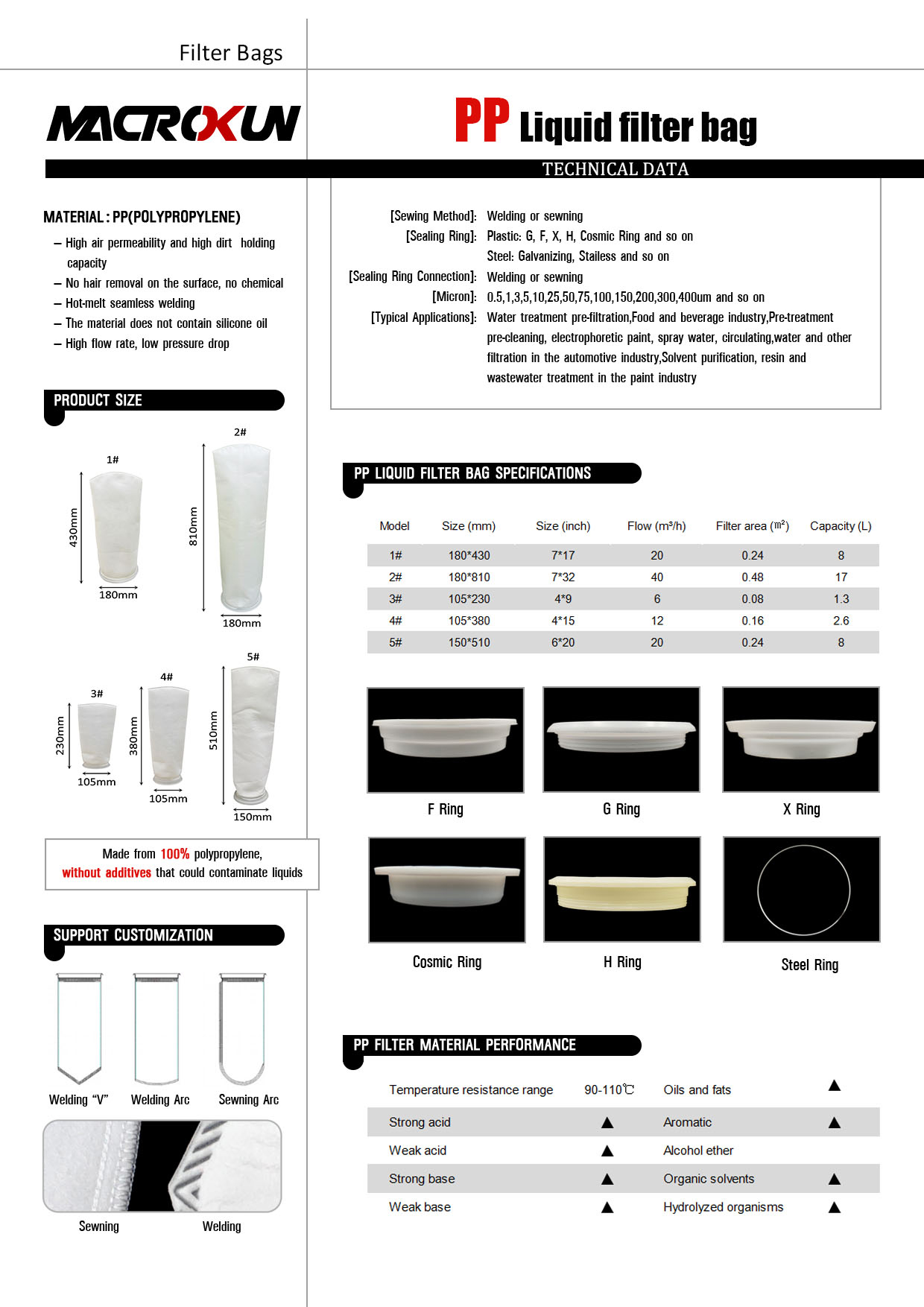

Our #2 Size Filter Bag Starter Pack includes twelve robust filter bags, each built on high‑loft polyester felt media with large nominal micron ratings. Specifically:

-

Media: Durable polyester felt recognized for mechanical strength, chemical resilience in aqueous streams, and easy handling.

-

High Micron Ratings: Four nominal ratings—50 µm, 100 µm, 200 µm, and 300 µm—three bags of each to cover a wide range of coarse‑filtration needs.

-

Ring Style: Polypropylene F‑flange collars that fit snugly into standard Size 2 housings, guaranteeing a bypass‑free seal.

-

Construction: Ultrasonic welded seams to eliminate stitch‑hole leakage, with reinforced collar attachments to withstand pressures up to 75 psi.

This configuration empowers you to tackle initial bulk‑removal stages without custom ordering each micron size.

Key Features of High‑Micron Polyester Felt Bags

When choosing coarse filters, these features ensure reliable performance:

1. Coarse, Surface‑Flow Filtration

-

50 µm & 100 µm: Remove fine silt, sand, and algae clumps in agricultural or water‑treatment applications.

-

200 µm & 300 µm: Ideal for weld spatter, pipe scale, and larger debris from industrial wash tanks.

2. Robust Polyester Felt Media

-

High‑Loft Construction: Offers large open channels for high flow and easy debris shedding.

-

Chemical & Temperature Tolerance: Suitable for water, mild acids/alkalis, and temperatures up to 180 °F.

3. Polypropylene F‑Flange Ring

-

Inert Seal: Resists pH 2–12 streams; flange locks securely to prevent bypass.

-

Universal Fit: Works with all standard Size 2 vessels—single, dual, or multi‑bag configurations.

4. Welded Seam Integrity

-

Seamless Media: Ultrasonic welds provide zero‑bypass along stitch lines, ensuring all liquid traverses the media.

-

Mechanical Strength: Collar attachment withstands flow surges and high differential pressures.

5. Starter Pack Convenience

-

Three Bags per Rating: Immediate coverage for shift‑based or batch‑driven changeouts.

-

Mixed Lengths: Optionally include both 10″ and 20″ lengths for vessels of varied heights.

These attributes combine to deliver dependable, high‑capacity bulk solids capture in demanding environments.

Choosing the Right High‑Micron Configuration

To optimize filtration, consider:

A. Micron Rating vs. Solids Profile

-

Coarse Debris (≥200 µm): Use 200 µm and 300 µm bags to efficiently trap large particles without rapid clogging.

-

Moderate Solids (50–100 µm): Deploy 50 µm and 100 µm ratings where finer silt or algae removal is needed before polishing.

B. Vessel and Flow Requirements

-

Single vs. Multi‑Bag Housings: Determine flow per bag; Size 2 bags support ~5–15 GPM each at low ΔP.

-

Bag Length: Choose 10″ for confined spaces; 20″ for extended runtimes at higher flow.

C. Process Chemistry & Temperature

-

Aqueous Systems: Polyester felt excels in water, mild acids, and caustics up to 180 °F.

-

Solvent Exposure: For hydrocarbon or strong solvents, consider alternative media; polyester may degrade.

D. Maintenance Strategy

-

Disposable: Quick bag swaps for hazardous or cross‑contaminated streams.

-

Reusable: Surface rinse and gentle backflush for non‑hazardous fluids to reduce waste.

By aligning micron rating, housing configuration, and maintenance approach, you’ll maximize both bag life and system protection.

Maintenance Best Practices

Ensure consistent performance with these guidelines:

1. Differential Pressure Monitoring

-

Install ΔP Gauges upstream and downstream. A rising ΔP indicates impending bag changeout—target thresholds of 15–20 psi.

2. Changeout & Disposal

-

Safe Removal: Use handle tools or gloves to prevent contact with contaminated bags.

-

Disposal: Non‑hazardous waste bags can be discarded per general industrial protocols; hazardous solids require compliant disposal.

3. Housing Upkeep

-

Interior Cleaning: Wipe housing walls and support elements at each change to remove settled debris.

-

Seal Inspection: Replace worn gaskets or O‑rings to sustain bypass‑free sealing.

4. Record Keeping

-

Usage Logs: Track volume filtered, ΔP at changeouts, and bag type to refine pack contents and change intervals.

-

Quality Checks: Periodically sample effluent turbidity to verify retention effectiveness.

Routine maintenance minimizes downtime, extends bag life, and protects downstream assets.

Why Choose Our High‑Micron Starter Pack?

Our #2 Size High‑Micron Starter Pack stands out through:

Comprehensive Rating Coverage

-

Four Coarse Levels: 50 µm, 100 µm, 200 µm, 300 µm bags address the full spectrum of bulk‑removal stages.

Quality Polyester Felt

-

Durable, High‑Loft Media: Engineered for high flow, easy cleaning, and robust chemical tolerance in aqueous processes.

Reliable Polypropylene Rings

-

Chemical Resistance: Seals securely in pH 2–12 fluids; flange design prevents bypass.

-

Standard Compatibility: Fits all Size 2 housings—single and multi‑bag.

Ultrasonic Weld Integrity

-

No Stitch‑Hole Leakage: Seamless bag bodies ensure all fluid passes through the felt matrix.

Pack Efficiency

-

Three Bags per Rating: Meets typical batch or shift‑based operations without overstocking.

Streamlined Inventory

-

Single SKU: Simplify procurement and shelf‑management with one comprehensive part number.

By bundling these benefits, our starter pack delivers immediate readiness and cost‑effective bulk filtration.

Illustrative Use Cases

Use Case 1: Industrial Parts Washer

A fabrication shop filters rinse water loaded with welding spatter (~200–300 µm). Installing 200 µm and 300 µm bags protected downstream reclaim pumps and reduced cartridge changes by 80%.

Use Case 2: Cooling Tower Makeup

An HVAC plant used 50 µm and 100 µm bags in a two‑stage setup to remove silt and algae. Bulk removal ahead of biocide injection improved chemical efficacy and reduced fouling.

Use Case 3: Pulp & Paper Slurry

A paper mill filters whitewater containing fiber clumps (~100 µm). 100 µm felt bags extended fine screen life and stabilized stock consistency.

Use Case 4: Food Processing CIP Water

A dairy plant recycles cleaning‑in‑place streams, removing cheese curd chunks (~50–200 µm) with 50 µm and 100 µm bags. Rapid bag swaps maintained production schedules.

These examples highlight the pack’s versatility in protecting equipment and ensuring process continuity.

Summary and Next Steps

The #2 Size Filter Bag Starter Pack, High Micron, Polyester Felt, Polypropylene Ring is your all‑in‑one solution for bulk solids control in Size 2 housings. Its mix of 50 µm to 300 µm bags, robust media, and slip‑proof collars ensures you’re ready for any coarse‑filtration challenge, from pilot systems to full‑scale operations.

Next Steps:

-

Assess Solids Profile: Identify particle sizes in your process to prioritize bag ratings.

-

Install ΔP Monitoring: Equip housings with gauges to optimize changeout timing.

-

Stock the Starter Pack: Secure immediate access to all high‑micron ratings.

-

Train Operators: Standardize changeout and disposal procedures for rapid response.

-

Evaluate Performance: Track flow rates, equipment uptime, and consumable usage to quantify pack ROI.

Incorporate this starter pack into your filtration strategy to maintain high flow, protect critical assets, and simplify your consumables logistics—delivering coarse‑filtration excellence day after day.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Next:Achieve Ultra‑Fine Filtration with #2 Size, 0.5 Micron Polyester Felt Liquid Filter Bags

Tags: