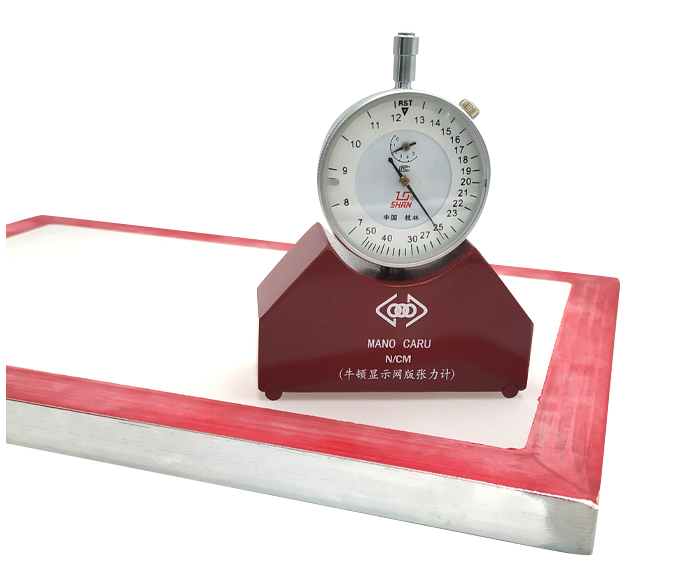

Newman Screen Tension Meter: The Durable, Accurate Choice for Consistent Prints

If precision, repeatability, and long-term value matter in your printroom, the newman screen tension meter deserves a hard look. This mechanical tension meter has earned a reputation among professionals for rock-steady readings, rugged construction, and a

If precision, repeatability, and long-term value matter in your printroom, the newman screen tension meter deserves a hard look. This mechanical tension meter has earned a reputation among professionals for rock-steady readings, rugged construction, and a service life that outperforms many cheaper alternatives. Below I’ll explain what makes it different, how it improves daily workflow, and why the right tension meter is one of the smartest investments a print shop can make.

Built to keep reading right — day after day

A tension meter is only useful if it remains accurate and reliable under shop conditions. The Newman meter distinguishes itself by a mechanical design focused on durability. Several product descriptions call out stainless hardened gears and jeweled bearings—components normally found in precision instruments—which reduce wear, resist shock, and keep internal mechanics stable over time. For shops that measure tension daily, that translates into fewer surprises and less downtime for repairs. sourceone.nazdar.comScreen Print World

Beyond rugged internals, Newman meters are commonly supplied with a protective case and a calibration glass, enabling quick field verification before use. That sort of ready-to-use package helps shops adopt consistent routine checks without extra equipment purchases. performancescreen.com

Accuracy and range that handle most shop needs

One of the reasons the newman screen tension meter is favored in many facilities is its useful measuring range and readable output. Typical 1E models report across a wide span (commonly specified 7–130 N or similar), which covers the requirements for most screen types and frame constructions. That full-span coverage lets a single instrument handle fine-mesh work and heavier frames alike, simplifying tool inventories. Lawson Screen & Digital Productsperformancescreen.com

When you measure both warp and weft at the same target band, registration stabilizes, halftones reproduce more faithfully, and you spend less time trouble-shooting inconsistent prints. In short: accurate, repeatable tension numbers lead directly to better, more predictable output.

Ease of use — designed for the production floor

Mechanical tension meters like Newman are straightforward to operate: place the meter on the mesh area, allow the mechanism to settle (some manuals recommend a light tap), read the dial, and rotate to check the perpendicular direction. Because the Newman design is mechanical and robust, many shops appreciate that it doesn’t require batteries or software—perfect when production doesn’t tolerate extra complexity.

But “simple” doesn’t mean “basic.” The thoughtfulness of a well-made mechanical movement makes readings feel solid and trustworthy. Most suppliers ship the meter with simple instructions and a quick reference for zeroing on the calibration glass, which helps operators adopt the tool quickly. stretchdevices.com+1

Why this meter is an investment, not an expense

Let’s be practical: any purchase must justify itself. The newman screen tension meter often sits in the mid-to-upper price band for mechanical meters, and buyers typically report that its longevity and consistent performance make it cost-effective over several years. With fewer repairs and dependable readings, shops avoid waste like failed exposure attempts, misregistered multi-color prints, or premature mesh replacement.

If you evaluate cost per year of service, a durable meter that cuts down on scrap and troubleshooting frequently pays for itself within a short time on moderate to busy production lines. Several resellers offer optional calibration certificates or periodic recalibration services if you need traceable verification for quality systems. sourceone.nazdar.comperformancescreen.com

How it fits into a practical tension control routine

Adopting a tension meter is as much about process as it is about hardware. Here’s a simple routine that shops use with the newman screen tension meter to get predictable results:

-

Zero and check — before the shift, place the meter on the supplied calibration glass to confirm zero and smooth needle behavior.

-

Center sample — measure in the screen center for both warp and weft. Record values.

-

Edge sampling — for larger frames, spot-check a few points near the edges to detect localized slack or over-stretch.

-

Tighten/retension — bring the lowest reading up to target, then re-check.

-

Log — keep a short record: date, operator, screen ID, and readings. Patterns of drift become obvious fast.

This routine prevents a lot of “it looked ok” problems and builds an objective history you can use to set maintenance intervals for mesh replacement or frame repair. Manuals and application notes from Newman and their distributors give the exact zeroing and handling tips that make these checks reliable. stretchdevices.comNBC Meshtec

Common buyer questions — answered

Q: Do I need a digital meter instead?

A: Digital meters offer convenience in logging and some have data output, but many shops prefer mechanical meters for their simplicity, lack of batteries, and long life. If data trending is critical for your QA program you can combine a mechanical Newman meter for rugged field checks with periodic digital audits.

Q: How often should I calibrate?

A: Daily zero checks on the calibration glass are prudent; full calibration or lab verification can be scheduled annually or per your quality policy—many suppliers offer NIST traceable calibration on request. performancescreen.com

Q: What if my meter gets bumped or dropped?

A: Even the most robust meters can be damaged by severe impacts. Newman’s shock-resistant internals reduce risk, but any sudden mechanical shock should prompt a quick zero check and, if readings look off, a service inspection.

Real-world results: what users report

Print professionals who choose the Newman meter commonly report improved registration and fewer exposure retries. They highlight consistent readings even after months of use and appreciate features such as the included calibration glass and the option for traceable certification. These practical outcomes—less scrap, reduced setup time, and more predictable runs—are the exact benefits you want when you buy a shop-grade instrument. shop.chromaline.comperformancescreen.com

Final thoughts — choose quality that supports your process

If you’re serious about control in your printroom, the newman screen tension meter is a practical, durable choice. It’s built to give operators confidence, produces readable numbers across a wide range, and pairs well with a straightforward tensioning routine. In a business where consistency equals profit, reliable tension measurement is a tiny investment that pays ongoing dividends.

Tension MeterPre:How to Calibrate Tension Meter — A Practical Guide and Why Proper Calibration Matters

Tags: