Why the right screen printing frame with mesh transforms your prints

The right screen printing frame with mesh shortens setup time, improves first-run success, and makes multicolor registration predictable. Invest a little time in matching mesh count, frame material, and finish to your inks and substrates — the payoff is c

Choosing the correct screen printing frame with mesh is one of the simplest decisions that leads to dramatically better results on press. Whether you run a home studio, a boutique setup, or a production house, the frame-and-mesh combination determines registration stability, detail resolution, ink deposit, and the repeatability of every run. In short: pick the right assembly once, and you’ll spend less time fixing problems and more time producing great work.

What a frame-and-mesh kit actually provides

A typical screen printing frame with mesh arrives as a ready-to-use unit: a rigid frame (aluminum or wood) with polyester or monofilament mesh stretched and secured to the frame surface. The best vendors will specify mesh count, thread diameter, and whether the screen is pre-stretched or intended for remeshing. Buying a ready screen saves setup time compared to stretching your own mesh; buying a remeshable frame gives you flexibility if your workflow changes. When you order, be sure the product data lists mesh count and recommended uses.

Wood or aluminum: which frame material suits your shop?

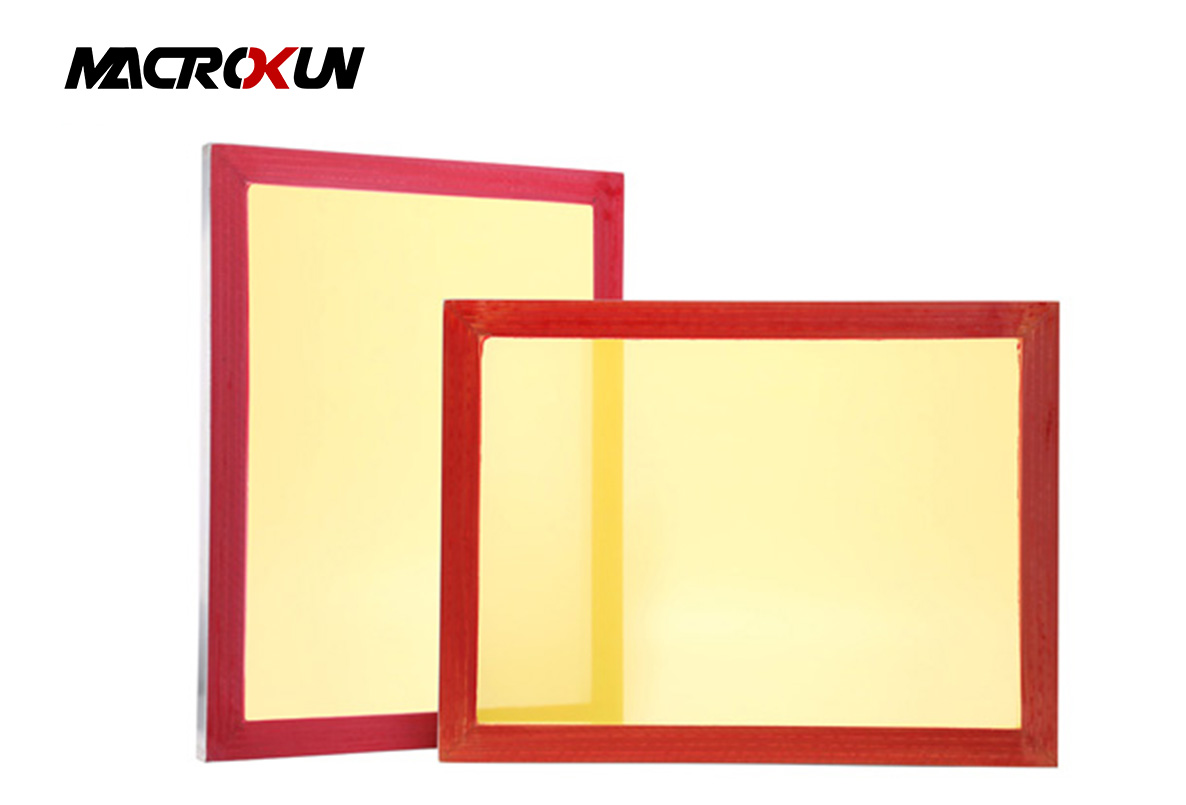

One of the first choices for anyone buying a screen printing frame with mesh is the frame material. Wood frames are cost-effective and good for short runs or teaching environments; however, they are heavier and less stable over time. Aluminum frames, by contrast, are lighter, resist warping, and maintain higher tension across many runs — which means crisper prints and longer screen life. For shops that value repeatability and quick registration, aluminum frames are frequently the better investment.

Mesh counts explained — how to pick the right mesh for your job

Mesh count (or mesh number) is the primary parameter that links design to outcome. Low mesh counts (for example, 110–160) pass more ink and are ideal for blocky graphics, heavy coverage, and printing on textured substrates. Higher mesh counts (200–230 and above) produce finer detail and are essential for halftones or high-resolution artwork. A well-specified screen printing frame with mesh will clearly state the mesh count and recommended use cases so you can match it to your artwork, ink type, and substrate.

Mesh tension and registration — why pre-stretched screens matter

Tension stability affects registration precision and image fidelity. A pre-stretched screen printing frame with mesh offers consistent tension out of the box and reduces variables during setup. This is particularly important for multi-color work where micro-shifts cause ghosting. If you prefer to stretch yourself to control tension values, choose a remeshable frame that supports your stretching equipment — but for speed and reliability, pre-stretched frames are a practical choice for many shops.

Mesh material and thread type — polyester, nylon, and specialty meshes

Most commercial screens use polyester mesh for its balance of durability, dimensional stability, and cost. Nylon meshes appear in some specialty applications where different elasticity or solvent behavior is needed. There are also monofilament and multifilament constructions; monofilament mesh tends to give cleaner lines and is preferred for fine detail and technical printing. When choosing a screen printing frame with mesh, check whether the mesh is monofilament polyester and whether the supplier provides uniformity specs — consistent thread diameter and weave quality produce more predictable prints.

Single-screen examples — how a wrong mesh ruins a run

Consider a simple t-shirt job: you choose a mesh intended for halftone detail but you’re actually printing a thick white underbase. The mesh will clog, the deposit will be insufficient, and you’ll re-run the job with a lower mesh screen — wasting time and materials. Choosing the right screen printing frame with mesh from the start avoids these mistakes: match mesh count to the intended ink deposit and detail level, and you’ll get first-pass success more often.

Size, aspect ratio and workflow planning

Frame size matters beyond simply “how big the image is.” Larger frames can distribute tension differently and may require stiffer frames to avoid deflection. Consider the exact platen and tooling on your press when ordering a screen printing frame with mesh—a frame that fits your clamps and provides the right clearance simplifies registration and trimming. Many pro shops standardize on one or two frame sizes to reduce changeover time and to make inventory predictable.

Finishing touches: edge treatment, splines and coatings

How the mesh is fixed to the frame affects durability. Splines, adhesive beads, or welded edges each have pros and cons. Some frames come with factory-applied edge reinforcement or pre-taped margins to protect emulsion and extend life. If you plan heavy-duty washups or reclaims, look for a screen printing frame with mesh that specifies reinforced edges or a remeshable design, because those features will save time and reduce tear risks during reclaiming.

Choosing mesh for different inks and substrates

Ink rheology interacts with mesh in predictable ways. Water-based inks often require different mesh choices than plastisol or solvent-based inks due to viscosity and flow behaviour. For heavy plastisol fills use a lower mesh count on your screen printing frame with mesh; for fine halftones and discharge work choose higher mesh counts and finer thread diameters. Suppliers that describe ink compatibility will help avoid cross-application surprises.

Durability, reclaiming and long-term costs

A well-constructed screen printing frame with mesh should withstand multiple reclaims if you plan to reuse frames. Aluminum frames with properly attached mesh and splines tend to survive many cycles better than cheaper wooden frames. Evaluate total cost of ownership: a higher upfront cost for a durable frame often pays back through fewer re-stretches, fewer ruined jobs, and less downtime—especially in production contexts.

Buying strategy — sample first, standardize later

For both small shops and production houses a smart pattern is: buy a sample set (several mesh counts and frame types), run representative jobs, then standardize on the surfaces that performed best. Buy a few pre-stretched screen printing frame with mesh units for rapid jobs, and keep a remeshable aluminum frame or two for custom tensions or specialist work. This hybrid approach blends speed and flexibility while controlling inventory costs.

Quick checklist before you buy a frame-and-mesh assembly

-

Confirm frame size and whether it fits your press clamps.

-

Choose frame material (aluminum for production; wood for economy).

-

Select mesh count based on detail vs deposit goals.

-

Check whether mesh is monofilament polyester for consistent lines.

-

Ask about pre-stretched vs remeshable options and tension specs.

-

Verify edge finishing and reclaim compatibility.

This practical checklist ensures the screen printing frame with mesh you buy is ready for your workflow, not a source of surprises.

Final thought — small choice, big impact

The right screen printing frame with mesh shortens setup time, improves first-run success, and makes multicolor registration predictable. Invest a little time in matching mesh count, frame material, and finish to your inks and substrates — the payoff is consistent prints, fewer reruns, and less stress on press day. When you get that foundation right, everything else becomes easier.

Pre:Dry Sift Screen Supplies-How To Use A Dry Sift Screens Set Effectively

Next:Why choosing the right aluminium screen printing frame changes every run

Tags: