Why an a4 screen printing frame is the perfect small-format solution

A small apparel studio used a set of four a4 screen printing frames (two pre-stretched at different mesh counts, two remeshable aluminium frames) to prototype designs. They were able to iterate color and halftone choices in a single afternoon, then scale

When you need consistent, repeatable small-format printing — postcards, small posters, stickers, patches or single-color t-shirts — an a4 screen printing frame gives you the sweet spot between control and convenience. It’s small enough to handle easily, large enough for most everyday artworks, and easy to store. For studios or hobbyists who want professional-looking results without big equipment, the a4 format lets you run quick jobs, test proofs, and produce finished pieces with minimal set-up time.

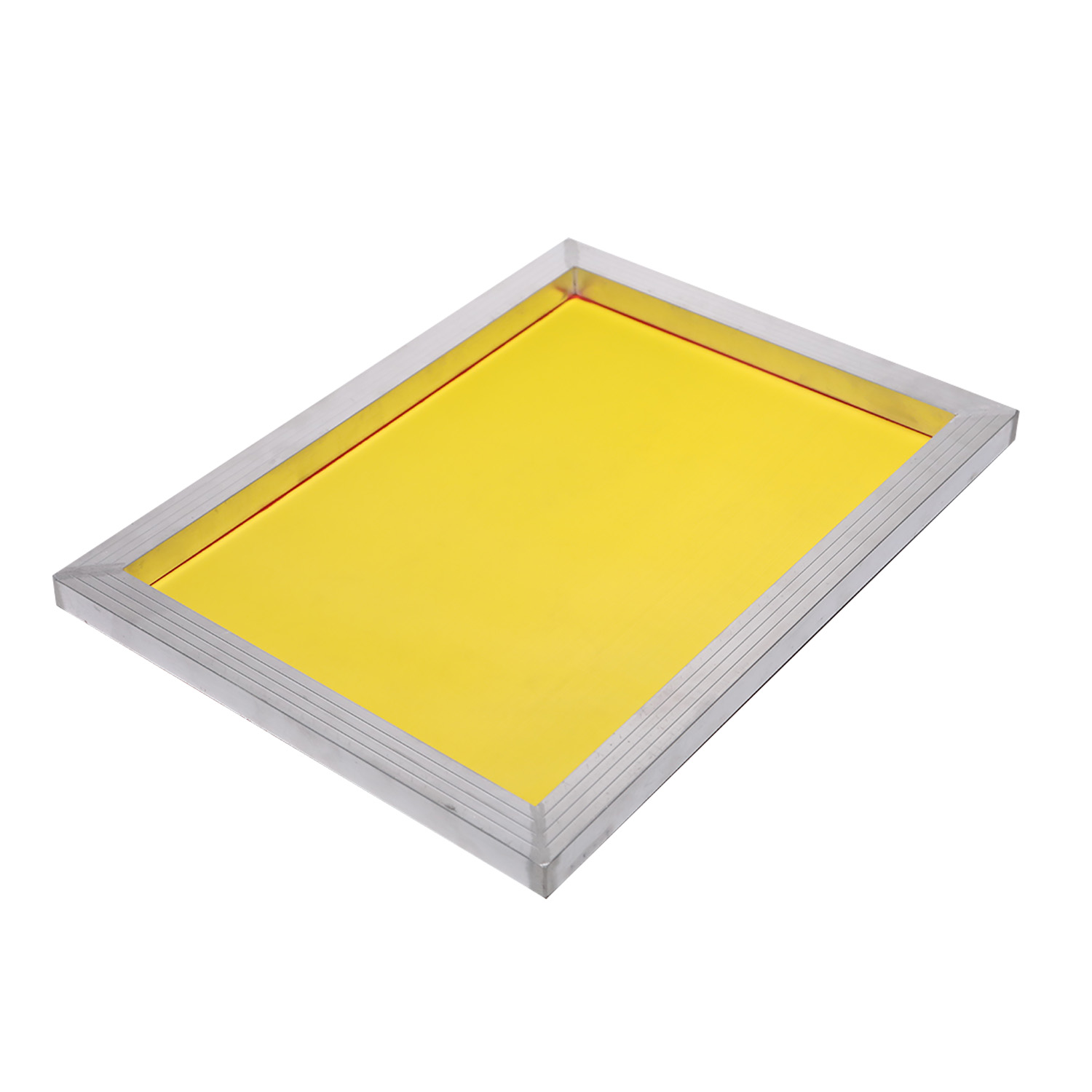

What an a4 screen printing frame actually is

Put simply, an a4 screen printing frame is a screen sized to comfortably accept artwork near the A4 paper dimensions while leaving a practical printing border. Typical ready screens and kits specify both the outer frame dimensions and the printable (inside) area so the buyer knows at a glance whether the frame will hold the intended print. Because of their familiar footprint and predictable handling characteristics, a4 screens are widely used as training, sample and small-run production tools.

Who uses an a4 screen printing frame — real-world use cases

Hobbyists and designers use a4 frames for proofing and short runs; small apparel brands use them for limited-edition runs and pre-production samples; craft sellers use them to produce greeting cards, labels and small art prints. In classrooms and workshops an a4 frame is ideal because it’s economical, easy to store, and low-risk — students can learn exposure, registration and ink mixing on a manageable scale. In every case the same practical advantages appear: lower material waste, quicker setup, and less storage footprint.

Typical dimensions and printable area — what to expect

Manufacturers of small-format screens publish both the external frame size and the printable area; for many A4-format frames this printable area sits slightly smaller than the nominal A4 paper size to allow for edges and squeegee clearance. Suppliers often quote an outer frame around a few millimetres larger than the printed area so you can clamp and handle the screen without interfering with the artwork. When you compare frames, pick one where the printable region matches or slightly exceeds the artwork you plan to run. georgeweil.com+1

Materials and construction: wood, aluminium and mesh basics

A4 frames come in two common frame materials: wood and aluminium. Wood is economical and suitable for short runs and classrooms; aluminium is lighter, flatter and far more stable under tension, which matters when you want sharp detail or repeatable registration. Mesh choices (monofilament polyester is most common) and mesh counts determine how much ink passes through: lower mesh counts deposit more ink, higher mesh counts give finer detail. For an a4 frame intended for varied small jobs, a mid-range mesh count strikes a good balance between clarity and deposit.

Choosing mesh count for your a4 screen printing frame

Don’t treat mesh as an afterthought. For small-format work an a4 screen printing frame fitted with lower mesh (e.g., 110–156) favors opaque fills and heavy coverage (good for bold graphics or plastisol), while higher meshes (200–305+) are better for halftones, line art and water-based inks. If you’re balancing versatility, pick a mid-range mesh or keep a small set of a4 screens with different mesh counts — that gives you the flexibility to switch between heavy fills and detail without re-stretching.

Pre-stretched vs remeshable a4 screen printing frame — quick decision guide

Pre-stretched and pre-tensioned a4 frames are ready to print straight away — they’re ideal if you want speed and consistent tension out of the box. Remeshable frames, on the other hand, let you replace mesh without replacing the frame, which can save money if you plan to change mesh counts frequently. For hobbyists and classrooms, pre-stretched a4 frames are convenient; for a studio that needs to test many mesh counts, a remeshable aluminium a4 frame is a small investment that pays back in flexibility and lower recurring cost. sourceone.nazdar.com+1

How to prep artwork and templates for an a4 screen printing frame

Design for the frame: when you prepare files for an a4 screen printing frame, set the artboard close to the printable area rather than the outside frame edge and add a comfortable border (usually 10–30 mm) so the squeegee can travel cleanly. Vector artwork at 300 dpi or higher is ideal; halftones should be screened at a frequency appropriate to the mesh count you’re using. Many small print service pages provide templates sized to common small-frame printable areas — use those to get consistent registration and avoid surprises.

Exposure, emulsion and curing tips for small screens

Because an a4 screen printing frame has a small surface area, exposures tend to be easier to manage than large frames — light passes through the emulsion more evenly and stencils reveal cleanly, provided you follow manufacturer exposure charts. Use the same emulsion-to-light-distance rules you’d use for larger screens, but shorten exposure times slightly if the supplier recommends it for small panels. Smaller screens also cure faster on press, so use them to test new ink formulas or curing temps before scaling up.

Practical testing routine — three quick checks before the first print

Before you run a batch on your a4 screen printing frame, do these three quick checks:

-

Alignment check — ensure the artwork sits within the printable area with at least 10–30 mm clearance on each side.

-

Test print — run a quick proof on the intended substrate to confirm color, coverage and registration.

-

Edge / squeegee behavior — verify that the squeegee angle and pressure produce the expected deposit without feathering; if not, try a slightly different bevel or durometer.

These small steps prevent the most common small-run issues and save ink and substrate.

Maintenance and reclaiming for small-format screens

Cleaning and reclaiming an a4 screen printing frame is quicker than large screens — less emulsion, less chemical, and less drying time. Use gentle reclaim processes to remove emulsion and avoid bending the frame. If you use aluminium a4 frames, they tolerate more aggressive reclaim cycles than wood frames. Keep a standard small reclamation station and a couple of spare pre-stretched a4 frames to swap during busy sessions — that keeps production flowing with minimal down-time.

Buying tips — what to ask the supplier

When you buy an a4 screen printing frame, request: outer and printable (inside) area dimensions, mesh count and material, whether the frame is pre-stretched, frame material (aluminium or wood), and any sample or small-quantity pack options. If you plan to buy multiple units, ask about consistent tension specs and lot traceability — that helps keep prints consistent across runs.

(When comparing vendors, the ones that publish printable area and mesh count usually make it faster to decide which frame matches your project.)

A small case study: how a studio used a4 frames to accelerate prototyping

A small apparel studio used a set of four a4 screen printing frames (two pre-stretched at different mesh counts, two remeshable aluminium frames) to prototype designs. They were able to iterate color and halftone choices in a single afternoon, then scale chosen designs to larger press frames later. The time saved in setup and the reduced material waste from testing paid the small initial investment back within weeks.

Final recommendations — how to standardize your small-format workflow

If you run regular small-format jobs, standardize by keeping:

-

One or two pre-stretched a4 screen printing frames for immediate proofs.

-

One remeshable aluminium a4 frame for mesh swaps and experimental trials.

-

A small palette of mesh counts (low, mid, high) across those frames.

-

A simple exposure and test-print log to capture settings that worked.

With that kit you can run short professional jobs quickly, test new ideas with little waste, and scale confidently when a design needs larger-format production.

Pre:Why choosing the right standard screen printing frame size matters for your shop

Next:none

Tags: