Master Your Toolset with the Perfect Squeegee Handle for Screen Printing

Your choice of squeegee handle screen printing tool influences every aspect of your print operation—from ink flow and edge precision to operator comfort and consistency. By focusing on ergonomic design, durable materials, reliable blade attachment systems

A quality squeegee handle screen printing setup is the unsung hero of every successful print. While much attention goes to mesh counts, emulsions, and inks, the equipment that holds your blade often determines comfort, control, and consistency—especially during long runs or intricate designs. Whether you hand‑pull prints in a home studio, run a small custom apparel shop, or operate a busy commercial press, choosing the right squeegee handle for screen printing maximizes precision while minimizing fatigue.

This comprehensive guide follows a proven structure—market overview, product understanding, key features, selection advice, maintenance tips, reasons to choose our offerings, illustrative use cases, and actionable next steps—designed to help you confidently select and maintain the ideal squeegee handle for screen printing.

Market Overview: What Leading Content Highlights

A survey of leading blogs, tutorials, and product reviews on squeegee handle screen printing yields several recurring themes:

-

Ergonomics & Comfort. Articles emphasize cushioned grips, contoured shapes, and non‑slip surfaces that reduce hand strain during extended print sessions.

-

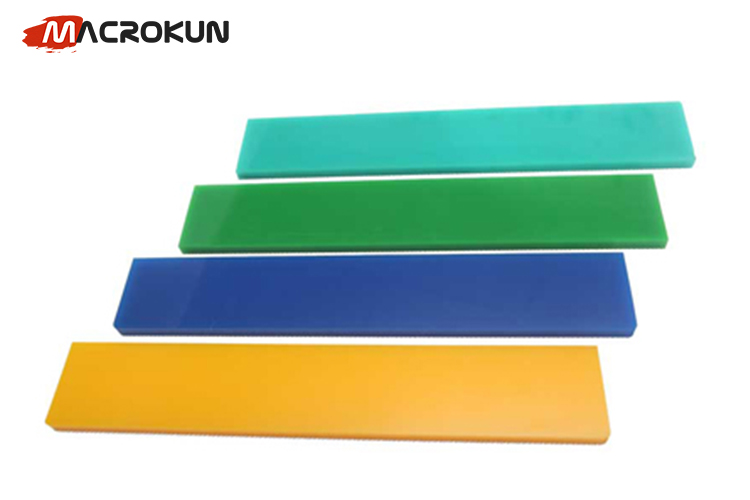

Durability & Material Quality. High‑quality handles often use hardwood, aluminum, or reinforced plastics noted for resistance to ink, solvents, and repeated use.

-

Blade Compatibility & Clamping Mechanisms. Guides cover various blade attachment systems—clamp bars, channel frames, and screw‑in designs—highlighting ease of changing blades and adjustability.

-

Handle Profile & Length. Discussions compare straight, pistol‑grip, and T‑bar styles, and examine how handle length affects leverage, control, and leverage.

-

Press vs. Hand Use. Content differentiates between handles designed for manual operation and those meant to mount on semi‑automatic or automatic presses, underscoring stability under mechanical pressure.

-

Maintenance & Upkeep. Advice on cleaning, inspecting, and replacing wear‑parts—such as rubber inserts or clamping screws—is frequently offered to maintain precision.

These common points illustrate that material, design, and blade retention mechanisms define the performance of a squeegee handle in screen printing.

Understanding the Squeegee Handle for Screen Printing

A squeegee handle screen printing tool is the frame or grip that holds the squeegee blade. It transfers the operator’s motion and pressure to the blade, ensuring uniform ink distribution across the screen. Although it might seem simple, a well‑designed handle:

-

Enhances Control: Ergonomic contours guide finger placement to steady strokes.

-

Improves Comfort: Padded or shaped grips reduce muscle strain during repetitive pulls.

-

Maintains Precision: Robust clamping systems hold blades securely at consistent angles.

Choosing the right handle aligns blade width and profile with printing method—hand‑pulled or press‑mounted—ensuring each pass lays down ink evenly and predictably.

Key Features of a Superior Screen Printing Squeegee Handle

When evaluating squeegee handles, consider these essential characteristics:

1. Ergonomic Grip Design

-

Contoured Shapes: Molds to natural hand posture, reducing cramping.

-

Non‑Slip Surfaces: Textured or rubberized coatings offer traction, even with ink‑stained hands.

-

Padded Sections: Soft inserts absorb pressure for long sessions.

2. Durable Construction Materials

-

Hardwood: Traditional feel, excellent resistance to solvents, minimal flex under pressure.

-

Aluminum or Stainless Steel: Lightweight yet sturdy, impervious to warping or moisture.

-

Reinforced Polymers: Cost‑effective, impact‑resistant, with chemical‑resistant finishes.

3. Secure Blade Attachment

-

Clamp Bar Systems: Allow quick blade swaps; tighten evenly across blade width.

-

Channel Frames: Slide blades into aluminum channels; set screws lock in place.

-

Screw‑In Handles: Blade seats directly into a T‑slot, then secured with screws at each end.

4. Handle Profile Options

-

Straight Bar: Classic design for direct control, popular in hand‑pulled setups.

-

Pistol Grip: Angled handle offers leverage, comfortable wrist alignment.

-

T‑Bar: Broad thumb rest and finger space for stable, two‑handed use on wide blades.

5. Length and Width Compatibility

-

Custom Lengths: Handles sized to match blade widths (e.g., 4”–36”), ensuring minimal overhang.

-

Press Mounts: Handles with bracket holes or adapters to fit screen printing presses or table mounts.

6. Maintenance‑Friendly Design

-

Replaceable Inserts: Rubber or foam grip pieces that can be swapped out as they wear.

-

Accessible Fasteners: Screws and bolts designed for common tools, simplifying blade changes and repairs.

-

Smooth Finish: Easy to wipe clean, preventing ink buildup in crevices.

By focusing on these features, you equip yourself with a handle that improves print quality, reduces operator fatigue, and endures daily use.

Choosing the Right Squeegee Handle for Screen Printing

Selecting the optimal handle involves matching design to your printing context:

A. Determine Printing Method

-

Hand‑Pulled Printing: Prioritize ergonomic grips and comfortable shapes for manual strokes.

-

Semi/Automatic Press: Look for handles with mounting brackets or press‑compatible end fittings and stiff materials to resist mechanical flex.

B. Match Blade Width and Handle Length

-

Small Designs: Shorter handles (4”–8”) fit narrow blades, enhancing control over tight spaces.

-

Large Prints: Longer handles (12”–24”+) span wide blades for single‑pass coverage, minimizing inconsistent pressure.

C. Select Handle Profile Based on Ergonomics

-

Straight Bar: Direct, traditional feel; ideal for straightforward printing motions.

-

Pistol Grip: Natural wrist position reduces strain, especially beneficial for vertical press setups.

-

T‑Bar: Allows two‑handed operation for very wide blades or heavy‑ink applications.

D. Choose Material for Your Environment

-

Home Studio/Classroom: Reinforced polymer offers a balance of durability and affordability.

-

Commercial Shop: Hardwood or metal handles withstand harsh cleaners, heavy use, and high‑throughput demands.

E. Consider Maintenance & Spare Parts

-

Blade Swap Frequency: If changing blades often, choose clamp bar or channel systems that facilitate quick, even tightening.

-

Grip Wear: Handles with replaceable grip inserts or modular designs ensure long‑term comfort without full handle replacement.

F. Evaluate Budget vs. Longevity

-

Entry‑Level: Reinforced plastic handles keep upfront costs low while offering good performance.

-

Professional‑Grade: Invest in metal or hardwood handles with robust clamping for superior precision and lifespan.

By assessing your printing style, blade sizes, volume, and workspace, you can pinpoint the handle design that optimizes control and comfort.

Maintenance and Care

Proper care of your squeegee handle screen printing tool ensures it remains reliable and comfortable:

1. Regular Cleaning

Wipe down handles after each session with a damp cloth and mild cleaner. Avoid soaking wood or metal handles to prevent warping or corrosion.

2. Inspect Fasteners and Clamps

Check screws, bolts, and clamps for tightness before each print run. Loose attachments cause blade slippage and unpredictable results.

3. Replace Worn Grips

Over time, foam or rubber inserts may lose elasticity. Swap them out for replacement grips to maintain ergonomic benefits.

4. Lubricate Moving Parts

If your handle features sliding clamps or bracket mounts, a light application of machine oil prevents rust and ensures smooth operation.

5. Store Properly

Hang handles or lay them flat in a clean, dry area. Avoid placing heavy items on top, which can deform grips or bend handles.

A little maintenance goes a long way in preserving print consistency and extending handle lifespan.

Why Choose Our Squeegee Handles for Screen Printing

Our squeegee handle offerings stand out thanks to:

Premium Materials & Craftsmanship

We source hardwoods with tight grain patterns, durable aluminum alloys, and reinforced polymers—all finished to resist ink, solvents, and wear.

Diverse Profiles & Sizes

From 6” to 36” lengths and straight, pistol, and T‑bar profiles, our handles accommodate every blade width and printing style.

Robust Blade Attachment Systems

Our clamp bars and channel holders ensure even, secure blade retention. Quick‑release designs make blade swaps fast, precise, and tool‑friendly.

Ergonomic, Replaceable Grips

Non‑slip rubber and foam inserts cradle your hand comfortably. When grips eventually wear, ordering replacements is simple—no need to replace the entire handle.

Press Compatibility

Optional mounting brackets and adapters integrate seamlessly with manual, tabletop, and semi‑automatic presses, ensuring stable, repeatable operation.

Stringent Quality Control

Every handle undergoes dimensional checks, material inspections, and clamp‑torque testing—guaranteeing you receive a tool ready for professional use.

Expert Support & Resources

While avoiding overt SEO jargon, our team provides clear advice on handle selection, blade matching, and maintenance routines to help you optimize your printing setup.

By combining superior materials, precise manufacturing, ergonomic design, and practical accessories, our squeegee handles help you achieve consistent, high‑quality prints while reducing operator fatigue and downtime.

Illustrative Use Cases

Use Case 1: Small Home Studio

An independent artist printing on apparel and paper used a 10” straight‑bar polymer handle. The lightweight design and non‑slip grip made long print sessions more comfortable, and the quick‑release clamp bar allowed rapid blade changes for mixed media projects.

Use Case 2: Boutique Clothing Line

A fashion label producing limited runs selected 14” hardwood T‑bar handles. The broad grip allowed two hands for stable control over large front prints, and the robust clamping system held thick medium‑durometer blades securely for consistent ink laydown.

Use Case 3: Commercial Print Shop

A high‑volume shop running semi‑automatic presses integrated 18” aluminum handles with press‑mount brackets. The stiff material and precise mount fittings eliminated blade wobble at high speeds, improving registration and reducing misprints by 25%.

Use Case 4: Art School Workshops

An educational studio equipped multiple workstations with 8” pistol‑grip polymer handles. Students appreciated the intuitive grip and balanced feel, which helped them learn proper tooling techniques quickly. Replaceable grips kept costs down as inserts wore out.

These scenarios demonstrate how matching handle design, material, and clamping method to your printing environment enhances print quality, comfort, and efficiency.

Summary and Next Steps

Your choice of squeegee handle screen printing tool influences every aspect of your print operation—from ink flow and edge precision to operator comfort and consistency. By focusing on ergonomic design, durable materials, reliable blade attachment systems, and maintenance‑friendly features, you equip yourself to produce sharper prints, reduce downtime, and minimize fatigue.

Reflect on your printing setup: What blade widths and profiles do you commonly use? Are you printing by hand or on a press? How long are your typical print runs, and do you experience discomfort or slippage? Use these insights to evaluate whether your current handles meet your needs or if upgrading to our premium squeegee handles could streamline your workflow.

Take action today by reviewing your handle inventory, selecting the right profiles and lengths for your blades, and setting up a maintenance routine to keep clamps tight and grips fresh. Investing in the perfect screen printing squeegee handle will pay dividends in comfort, consistency, and productivity—empowering you to achieve flawless prints with every pull.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Pre:Master Your Prints with the Ideal Squeegee for Silk Screen Printing

Next:Unlock Superior Prints with the Right Squeegee Rubber for Screen Printing

Tags: