Master Your Prints with the Ideal Squeegee for Silk Screen Printing

Your choice of squeegee for silk screen printing plays a pivotal role in print clarity, color vibrancy, and workflow efficiency. By understanding blade materials, durometer hardness, edge profiles, handle ergonomics, and proper maintenance, you can select

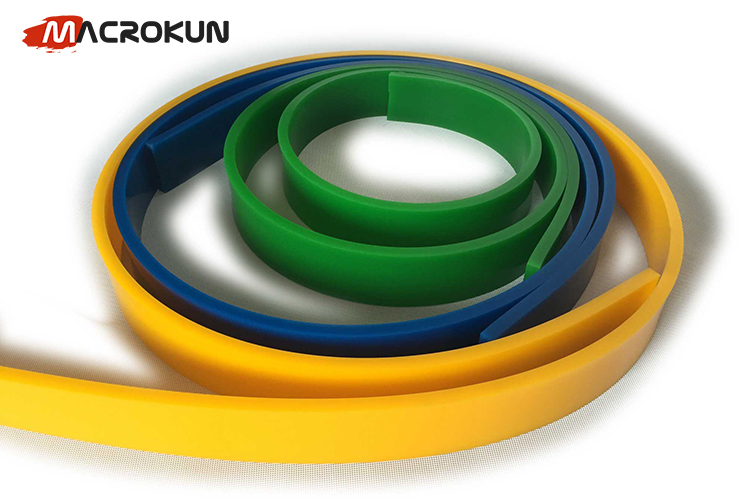

In the realm of screen printing, the tool that bridges your design and final product is the squeegee. When you’re working with silk screen printing, choosing the right squeegee for silk screen printing is essential to achieve crisp details, vibrant colors, and consistent results. Whether you run a boutique apparel shop, produce posters, craft fine‑art prints, or teach a classroom of aspiring printers, understanding how to select, use, and maintain your squeegee will elevate every project.

This guide follows a proven structure—market overview, product understanding, key features, selection guidance, maintenance tips, reasons to choose our offerings, illustrative use cases, and actionable next steps—so you can unlock the full potential of your silk screen printing squeegee.

Market Overview: Common Themes Around Silk Screen Printing Squeegees

A review of leading content on “squeegee for silk screen printing” reveals several recurring themes:

-

Material & Durability

Premium squeegees emphasize polyurethane or rubber blades designed for resistance to abrasion, ink solvents, and repeated use. -

Durometer Options

Guides consistently discuss Shore A hardness ratings—soft, medium, and hard—and how each level affects ink deposit and edge definition. -

Edge Profiles

Square, beveled, and rounded edges are covered extensively, showing impact on ink flow, line sharpness, and substrate adaptability. -

Handle & Holder Designs

Ergonomic grips, balanced weight, and secure blade fixtures are highlighted as critical for operator comfort and pressure consistency. -

Compatibility with Inks & Mesh

Advice frequently covers matching blade hardness to ink type (plastisol, water‑based, discharge) and mesh counts (coarse to fine). -

Manual vs. Automatic Use

While many squeegees target hand‑pulled screens, robust models built for tabletop or automatic presses appear frequently. -

Maintenance & Replacement

Proper cleaning, edge inspection, blade rotation, and timely replacement are recommended to sustain print quality and extend squeegee life.

These themes underscore that material, hardness, edge shape, ergonomics, and care define a high‑performance squeegee for silk screen printing.

Understanding the Squeegee for Silk Screen Printing

A squeegee for silk screen printing is the handheld or press‑mounted tool featuring a flexible blade attached to a handle or frame. During printing, the blade presses ink through the fine mesh of a silk screen onto the substrate below. Though it may seem simple, a squeegee’s design intricacies—blade compound, hardness, profile, and handle ergonomics—crucially influence:

-

Ink Deposit: How much ink is pressed through the mesh.

-

Line Sharpness: The crispness of print edges and small details.

-

Pressure Distribution: Evenness of force across the blade length.

-

Operator Comfort: Ease of use during repetitive strokes.

Understanding these components clarifies why investing in a properly engineered squeegee transforms your prints from good to exceptional.

Key Features of a High‑Performance Squeegee

When evaluating squeegees for silk screen printing, look for these core features:

1. Blade Material & Compound

-

Polyurethane: Exceptional abrasion and solvent resistance; retains shape under heavy use.

-

Natural or Synthetic Rubber: Offers flexibility and tack; may be preferred for specialty inks.

2. Durometer (Hardness) Range

-

Soft (50–60 Shore A): Flexes to push heavy inks through coarse meshes, ideal for textiles.

-

Medium (65–75 Shore A): Versatile for general apparel, graphics, and moderate detail.

-

Hard (80–90 Shore A): Minimal flex for fine lines, small text, and thin inks on smooth substrates.

3. Edge Profile

-

Square Edge: Even ink coverage; suited for bold, solid areas.

-

Beveled Edge: Crisp release at trailing edge; excellent for moderate to fine detail.

-

Rounded Edge: Smooth stroke on textured surfaces; reduces mesh drag.

4. Blade Dimensions

-

Width: Must match design area and screen frame to minimize passes and maintain steady pressure.

-

Length: Should span the print area without overhang to prevent uneven ink distribution.

-

Thickness Tolerance: Consistent thickness ensures uniform pressure and ink laydown.

5. Handle or Holder Design

-

Ergonomic Grip: Non‑slip, contoured handles reduce hand fatigue during extended runs.

-

Balanced Weight: Proper weight distribution aids in even pressure application.

-

Secure Blade Clamping: Prevents blade slippage and angle shifts under pressure.

6. Compatibility with Inks & Mesh Counts

-

Ink Resistance: Blades must resist swelling or softening by water‑based, plastisol, and specialty inks.

-

Mesh Versatility: Ability to perform on coarse to ultra‑fine meshes by matching durometer and profile.

7. Maintenance & Serviceability

-

Easy Cleaning: Smooth surfaces facilitate prompt ink removal.

-

Blade Rotation: Designs allowing blade flipping distribute wear.

-

Regrinding/Replacement: Some blades can be re‑edged; quick replacements reduce downtime.

By ensuring your squeegee embodies these features, you set the stage for crisp, vibrant, and repeatable silk screen prints.

Choosing the Right Squeegee for Your Needs

Selecting the optimal squeegee involves matching blade specifics to your printing context:

A. Consider Ink Type & Viscosity

-

Heavy Plastisol or Specialty Inks: Soft to medium blades flex to push thicker ink through mesh.

-

Water‑Based or Discharge Inks: Medium to hard blades deliver precise, controlled laydown.

B. Factor in Mesh Count & Detail Level

-

Coarse Mesh (60–110): Use softer blades and square edges for bold coverage.

-

Mid Mesh (110–160): Medium blades with bevel edges suit most apparel prints.

-

Fine Mesh (160+): Hard blades angled precisely yield crisp lines and small text detail.

C. Match Substrate Characteristics

-

Textiles: Slightly softer blades adapt to fabric weave; ensure color opacity.

-

Paper, Plastics, Metal: Harder blades for sharp edges on smooth, rigid surfaces.

D. Evaluate Print Size & Pass Count

-

Large Front or Back Prints: Wider blades (12”–14”) minimize passes; medium durometer ensures flexibility and coverage.

-

Small Logos or Labels: Narrower blades (4”–8”) offer more control in confined spaces.

E. Decide on Manual vs. Press Use

-

Hand‑Pulled Screens: Ergonomic handheld squeegees with comfortable cores reduce fatigue; maintain consistent angle by wrist technique.

-

Semi/Automatic Presses: Press‑mountable rails or brackets work best with robust, secure blade attachments; consider layered blades designed for high‑speed use.

F. Budget & Lifecycle

-

Initial Cost vs. Durability: Premium blades cost more upfront but last longer; factor in replacement and downtime savings.

-

Availability of Spares: Ensure easy access to replacement blades or regrinding services to maintain production flow.

By systematically reviewing these factors, you can pinpoint the squeegee configuration—blade material, durometer, profile, dimension, and handle style—that aligns with your workflow, inks, meshes, and substrates.

Maintenance and Care

Proper upkeep of your squeegee for silk screen printing preserves performance and extends its life:

1. Clean Immediately After Use

Remove ink promptly using appropriate cleaners. Avoid letting ink cure on the blade, which can harden and damage edges.

2. Inspect Blade Edge Frequently

Examine for nicks, cuts, or uneven wear. Even minor defects create print streaks. Address issues by rotating or re‑edging.

3. Rotate or Flip Blade

If your design and width permit, use alternate edges to distribute wear more evenly and prolong blade life.

4. Regrind or Replace When Needed

For blades designed to be re‑edged, use proper tools or services to restore the edge profile. Replace blades once wear exceeds repairable limits.

5. Store Properly

Store squeegees flat or hung in a dry environment. Avoid pressure on the blade edge and exposure to extreme heat or sunlight, which can warp rubber.

6. Maintain Handle Integrity

Check clamps and fasteners for tightness. Inspect handles for cracks or wear and replace if structural integrity is compromised.

Consistent maintenance ensures each print starts with a sharp, uniform blade, minimizing defects and maximizing efficiency.

Why Choose Our Silk Screen Printing Squeegees

Our squeegee solutions are engineered to meet the exacting needs of silk screen printers:

Premium Material Formulation

We utilize high‑grade polyurethane compounds selected for superior abrasion, solvent resistance, and stable flex characteristics under heavy use.

Comprehensive Durometer Selection

From soft through hard, including multi‑layer options, our blades cover every ink type, mesh count, and substrate you encounter.

Precision‑Cut Edge Profiles

Square, beveled, and rounded edges are manufactured with tight tolerances, ensuring consistent thickness and smooth surfaces for reliable prints.

Ergonomic Handle Designs

Our handles feature non‑slip, contoured grips, balanced weight distributions, and secure clamp mechanisms to enhance comfort and control.

Manual & Press‑Mountable Versions

Whether you hand-pull screens or run semi‑automatic presses, we offer compatible fixtures and blade assemblies for seamless integration.

Strict Quality Control

Each blade and handle assembly undergoes dimensional, durometer, and material integrity inspections, guaranteeing consistent performance from the first print onward.

Dedicated Support

While avoiding overt SEO jargon, our team provides clear guidance on squeegee selection, maintenance best practices, and troubleshooting techniques—helping you achieve optimal results with minimal trial and error.

By combining cutting‑edge materials, precise engineering, ergonomic design, and expert support, our silk screen printing squeegees empower you to produce sharper, more consistent prints while reducing waste and downtime.

Illustrative Use Cases

Use Case 1: Boutique Apparel Line

A small fashion brand printing limited‑edition tees selected our 70 Shore A beveled‑edge blades. The combination of medium hardness and angled edge yielded vibrant colors with crisp detailing, reducing second‑print touch‑ups by 40%.

Use Case 2: Fine‑Art Print Series

An artist producing silk screen prints on heavyweight paper opted for our 85 Shore A square‑edge blades. The firmer durometer provided controlled ink laydown for intricate patterns, delivering gallery‑quality finishes.

Use Case 3: DIY Classroom Workshops

A community art center outfitted their printmaking studio with 60 Shore A rounded‑edge squeegees. Students found them easy to clean and forgiving of minor angle inconsistencies, making learning less frustrating and more productive.

Use Case 4: Promotional Merchandise Production

A print shop handling mixed runs of tote bags, posters, and shirts needed versatile squeegees. They maintained a stock of soft, medium, and hard blades in various widths, swapping blades between jobs for optimal coverage and detail on each substrate.

These examples show how matching squeegee characteristics to specific print contexts drives improvements in quality, efficiency, and operator satisfaction.

Summary and Next Steps

Your choice of squeegee for silk screen printing plays a pivotal role in print clarity, color vibrancy, and workflow efficiency. By understanding blade materials, durometer hardness, edge profiles, handle ergonomics, and proper maintenance, you can select tools that consistently deliver professional results, reduce waste, and enhance operator comfort.

Reflect on your upcoming projects: What inks, meshes, and substrates will you use? How detailed are your designs, and what print volumes do you anticipate? Evaluate whether your current squeegee setup meets these needs or if upgrading to premium blades and ergonomic handles could improve your outcomes.

Take action today by auditing your squeegee inventory, testing different durometers and profiles on sample prints, and implementing a maintenance routine that keeps blades in prime condition. Investing in the right squeegee for silk screen printing will pay dividends in sharper prints, fewer errors, and streamlined production—empowering your creative vision and your business success.

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Pre:Elevate Your Prints with the Speedball Screen Printing Squeegee

Next:Master Your Toolset with the Perfect Squeegee Handle for Screen Printing

Tags: