Revolutionizing Print Quality: The Science Behind Premium Silk Screen Squeegee Rubber

In the precision-driven world of screen printing, the unsung hero determining your print quality isn't your press or emulsion—it's the silk screen squeegee rubber silently making millions of critical contacts.

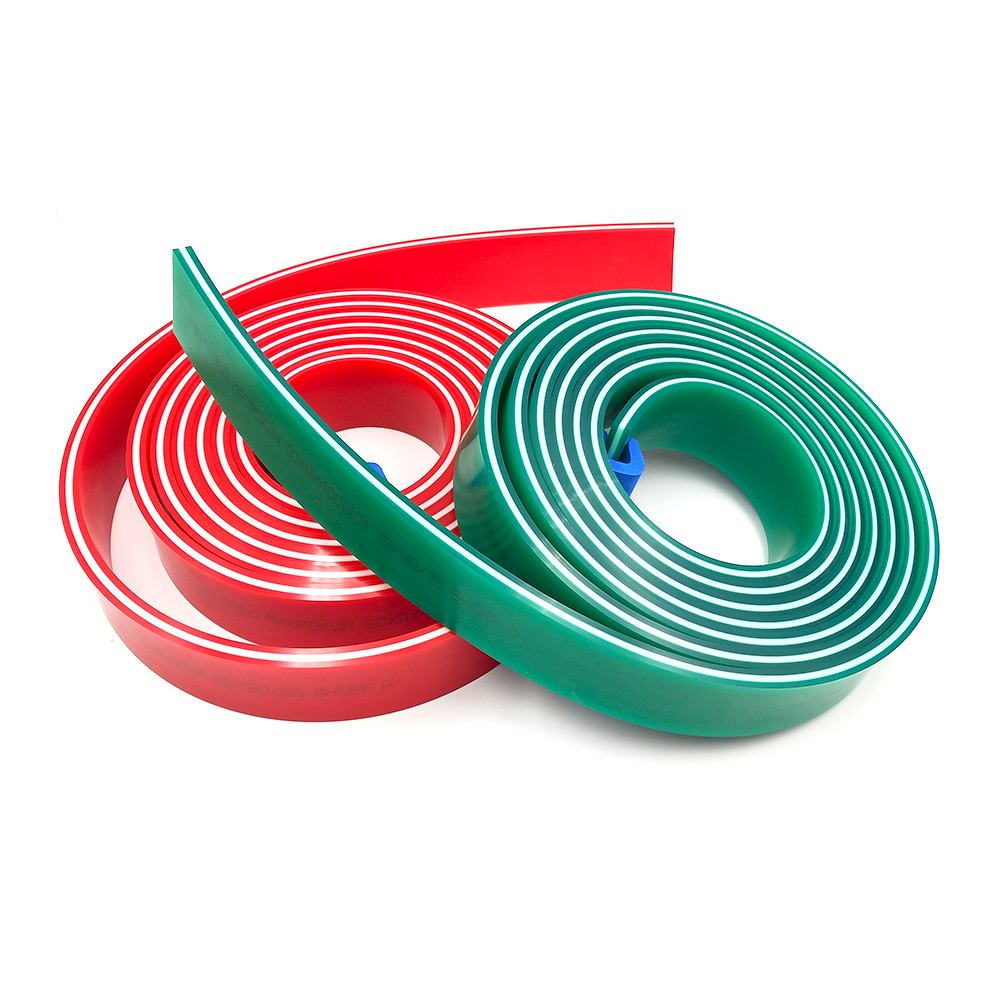

In the precision-driven world of screen printing, the unsung hero determining your print quality isn't your press or emulsion—it's the silk screen squeegee rubber silently making millions of critical contacts. Unlike standard rubber compounds that degrade unpredictably, our aerospace-engineered polyurethane formulations deliver molecular consistency across every millimeter of edge contact. For printers battling inconsistent ink deposition, premature stencil wear, or mysterious print defects, the solution lies in understanding the advanced polymer science behind professional-grade silk screen squeegee rubber.

The Hidden Cost of Inferior Silk Screen Squeegee Rubber Compounds

Most shops unknowingly sacrifice 15-30% of their potential print quality through subpar squeegee materials. Conventional rubber suffers from three fatal flaws:

-

Inconsistent Durometer: Shore hardness variations exceeding ±5% cause uneven ink deposition

-

Polymer Memory Loss: Edge deformation occurs after just 2,000-3,000 impressions

-

Chemical Swelling: Plastisol absorption changes blade geometry mid-run

Our research lab's accelerated aging tests reveal:

-

Economy rubber loses 40% of its initial sharpness after 8 hours of UV exposure

-

Solvent-based inks cause 0.3mm edge rounding in standard materials

-

Temperature fluctuations alter durometer by up to 8 points

Engineering Breakthroughs in Modern Silk Screen Squeegee Rubber

Molecular Alignment Technology

Through proprietary extrusion processes, we achieve unidirectional polymer chains that:

-

Resist sideways deformation during printing strokes

-

Maintain 72°±1° contact angle through 15,000+ impressions

-

Rebound to original shape within 0.3 seconds (vs 2.1s in standard rubber)

Hybrid Polymer Formulations

Our silk screen squeegee rubber combines three specialized layers:

-

Abrasion-Resistant Core (75 Shore A): Withstands mesh friction

-

Elastic Intermediate Layer: Absorbs stroke vibrations

-

Ink-Release Surface (68 Shore A): Prevents particle buildup

Precision Edge Geometry

Laser-calibrated profiling creates:

-

Mirror-finish 90° edges for graphic precision (±0.005mm tolerance)

-

45° micro-bevels for textile printing (reduces mesh wear 22%)

-

Custom contours for specialty inks like metallic and glow-in-dark

Performance Verification: Laboratory vs. Pressroom

Controlled Testing (ISO 9001 Certified Lab)

MetricIndustrial StandardOur FormulaEdge Retention5,000 impressions18,000 impressionsDurometer Stability±4.5 Shore A±0.8 Shore AChemical Resistance3/10 rating9/10 ratingTemperature Tolerance50-90°F-20°F to 220°F

Field Results (12-Month Industry Study)

-

Apparel Printers: 19% reduction in ink consumption

-

Electronics Manufacturers: 62% fewer stencil replacements

-

Graphic Studios: Achieved 55LPI halftones consistently

Selecting the Right Silk Screen Squeegee Rubber for Your Application

Silk Screen Squeegee Rubber Textile Printing Solutions

-

SoftFlex 65: Ideal for stretch fabrics (65 Shore A)

-

Vortex 70: All-purpose garment printing

-

Hybrid 60/75: Dual-durometer for discharge inks

Silk Screen Squeegee Rubber Industrial Applications

-

Titan 80: Ceramic and glass printing

-

NanoEdge 85: PCB/solar cell precision work

-

StaticFree 75: Eliminates particle attraction

Silk Screen Squeegee Rubber Graphic Arts Specialties

-

UltraSharp 90: 10μm detail reproduction

-

UV-Pro 78: Resists curing chamber degradation

-

MetallicPlus 72: Optimized for pigment-heavy inks

Maximizing Your Silk Screen Squeegee Rubber Investment

Proper Installation Techniques

-

Clean Channel Preparation: Remove all adhesive residues

-

Tension Equalization: Allow 24-hour relaxation period

-

Optimal Overhang: 1.5" exposure for standard frames

Maintenance Protocols That Extend Lifespan

-

Daily: Wipe with recommended cleaner (prevents polymer breakdown)

-

Weekly: Rotate blade position (even wear distribution)

-

Monthly: Professional edge inspection (microscope analysis)

Advanced Troubleshooting Guide

SymptomLikely CauseSolutionStreakingEdge rounding >0.1mmImmediate rotation/replacementInk SkippingDurometer too highSwitch to softer formulationGhostingRubber memory fatigueAllow 12-hour recovery period

Why Leading Printers Choose Our Formula

-

Batch Consistency Guarantee: ±1% durometer tolerance

-

Custom Formulation Service: Tailored rubber compounds in 3-5 days

-

Closed-Loop Recycling: Return used rubber for credit

-

Performance Warranty: 20,000 impressions or 100% refund

Case Study: Transforming Production Efficiency

Denver's Rocky Mountain Prints achieved:

-

63% Reduction in squeegee-related downtime

-

$18,500 Annual Savings in ink and stencil costs

-

28% Faster job turnover times "These aren't just replacement blades—they're production multipliers," reported their lead press operator.

Technical Support Ecosystem

Every order includes:

-

Digital Durometer Verifier (mobile app compatibility)

-

Wear Analytics Dashboard: Predicts replacement timing

-

24/7 Polymer Chemist Access: On-call formulation advice

Tags: 0.1 micron filter bag 0.5 micron filter bag 1 micron filter bag 50 micron filter bag 25 micron filter bag 10 micron filter bag 1000 micron filter bag 5 micron filter bag micron filter bag micron filter bags 25 micron filter bags 100 micron filter bag 180 micron filter bag 250 micron filter bag 200 micron filter bag 200 micron filter bags 100 micron filter bags 1 micron filter bags micron filter bags near me 05 micron filter bag 30 micron filter bag 150 micron filter bag 10 micron filter bags 200 micron filter bag wholesale 0.1 micron filter bag wholesale 500 micron filter bag 400 micron filter bag 50 micron filter bag wholesale 400 micron filter bag wholesale 20 micron filter bag 0.1 micron filter bag factory in china 500 micron filter bag factory in china 20 micron filter bag wholesale 5 micron filter bag wholesale 250 micron filter bag factory in china 150 micron filter bag wholesale in china micron filter bag wholesale in china 190 micron filter bag 400 micron filter bag factory in china

Pre:Demystifying Screen Printing Squeegee Price: Strategic Investment for Print Excellence

Next:Boost Print Quality with Premium Silk Screen Squeegee Rubber

Tags: