Best screen printing squeegee — pick the one that gives you perfect prints, every time

Pick a blade that matches your day-to-day needs, keep a small set for specialty jobs, and prioritize urethane if you run solvent-based inks or long production cycles. Do that and your next runs will feel smoother, your halftones will pop, and your custome

When it comes to reliable output on your press, the squeegee is the unsung hero. The Best screen printing squeegee is not necessarily the most expensive or the most hyped — it’s the one that matches your inks, mesh, substrate, and workflow. Get that match right and prints snap into focus: cleaner halftones, fewer re-runs, consistent ink deposit, and predictable wear. Below is a practical, no-nonsense guide to choosing that squeegee — the exact blade, durometer, and edge profile that will help you print better, faster, and with less frustration.

Why the “best” squeegee depends on context

There isn’t one universal “best” tool for every job. The single most common mistake shops make is buying on brand or price alone and ignoring fit: mesh count, substrate texture, ink chemistry, and desired deposit. The real Best screen printing squeegee is the one tuned to these variables — a blade that holds a crisp edge under your inks, resists your cleaners and solvents, and matches the pressure profile of your press.

In short: define your job first, then choose the squeegee that solves that job.

Materials: choose the compound that survives your shop

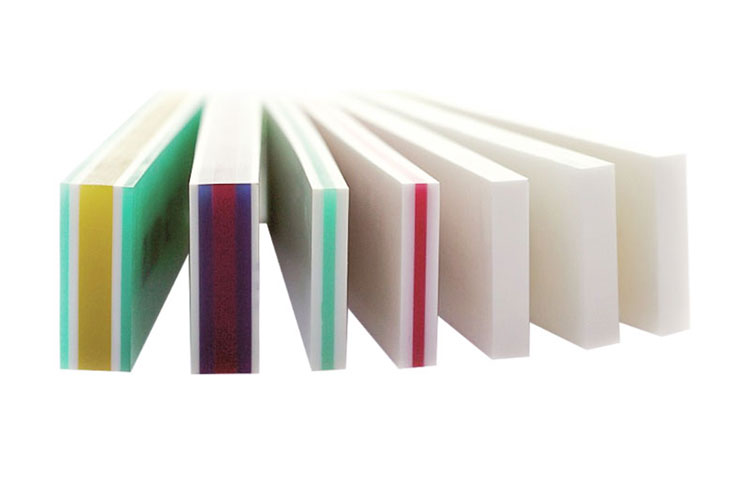

Squeegees are commonly made from three families of elastomers: natural rubber, neoprene, and polyurethane. Each has practical pros and cons:

-

Polyurethane (urethane): Industry-standard for production shops. Superb edge retention, solvent and abrasion resistance, and dimensional stability. Urethane blades often last multiple times longer than rubber under heavy use.

-

Neoprene: Good middle ground — more durable than natural rubber and generally more economical than premium urethane. Works well in many garment shops.

-

Natural rubber: Budget-friendly and flexible — fine for learning and hobby use but wears faster and can swell with solvents.

If your shop runs solvent-heavy inks or long automatic runs, polyurethane is the material that will give consistent edge life and predictable results.

Durometer: the single most impactful spec

Durometer is the measure of a blade’s hardness. It’s where you tune deposit, detail, and forgiveness. Typical behavior:

-

60–70 (soft): Conforms to uneven surfaces, lays down thicker ink, good for special effects and textured garments.

-

70–80 (medium): Versatile workhorse for most garment printing and general production.

-

80–90 (hard): Sharp contact, low deposit — ideal for high-mesh screens, fine halftones, and detailed artwork.

-

Multi-durometer (e.g., 70/90/70): Composite blades that combine a soft working edge with a stiff core — excellent for carrying large deposits without excessive flex.

A recommended starting point for many shops is a 70 durometer blade and a 70/90/70 composite for demanding jobs. Try samples to confirm. chromaline.com+1

Edge profile and bevel: how geometry controls ink laydown

Edge shape matters as much as material and hardness. Common profiles:

-

Square edge: More ink, softer wipe — useful for heavy fills and low mesh.

-

45° bevel: Balanced contact and release — an excellent general-purpose profile.

-

60° / 80° bevel: Sharper shear, cleaner halftones, crisper detail; use with higher mesh counts.

Pick a bevel based on whether you need greater deposit (square) or sharper definition (steeper bevel). Many pro shops keep a small set of blades with different bevels and durometers on hand.

Width and length: match the blade to the print area

Wider blades distribute pressure differently than narrow ones. For broad prints, a wider, slightly firmer blade prevents chatter and improves evenness. For small details and spot prints, a narrow blade with a finer bevel produces better definition. Consider blade height too: taller blades can store more energy and influence how the ink exits the mesh.

Practical tests that tell you if a squeegee is “best” for your setup

Before committing to bulk purchases, do three short prints with each candidate blade and score them on:

-

Coverage and deposit consistency across the print.

-

Halftone and edge definition in high-contrast areas.

-

Wear and handling after a few hundred pulls (does the edge burr or flatten?).

The blade that gives the best combined score for your inks, mesh and substrate is your Best screen printing squeegee — even if it isn’t the priciest.

Maintenance: how to keep a squeegee working longer

A few habits keep blades printing well and extend their life:

-

Store flat and away from solvents to avoid warping or softening.

-

Rotate blades so wear is even.

-

Re-bevel lightly with a sharp blade when edges dull; this restores crispness for a while.

-

Replace before catastrophic wear — a badly nicked or rolled edge ruins prints and can damage screens.

Urethane costs more up front but needs less frequent reconditioning than rubber.

Specialty constructions and advanced options

Modern squeegees come in engineered forms: bonded bevels, ribbed cores for lower drag, and triple-duro constructions that combine the best traits of soft and hard materials. For shops that push the limits — ultra-fine halftones, specialty inks, or long automation runs — these engineered blades often become the de facto Best screen printing squeegee because they balance deposit and stability.

Buying: what to ask your supplier

When you order, request the following information so you select the best blade for your needs:

-

Exact material compound (polyurethane grade if possible).

-

Durometer(s) and whether the blade is single or multi-duro.

-

Edge profile options and standard widths/lengths.

-

Sold-by options (inch, pre-cut handles, or rolls).

-

Any vendor sample or trial policy.

A vendor who supports samples and has clear durometer options helps you find the right blade fast.

Stocking strategy — keep the right set on the shelf

For most shops a simple three-blade kit covers >95% of jobs:

-

70 durometer (general work) — the daily workhorse.

-

80 durometer (detail/high mesh) — for crisp halftones and fine work.

-

70/90/70 or 70/80/70 composite (heavy deposit + stability) — for thick underbases and high-production jobs.

This minimal kit avoids downtime and gives operators the flexibility they need.

Troubleshooting quick-guide

-

Soft, muddy prints: use a harder durometer or a steeper bevel.

-

Too little deposit: softer blade or square edge may help.

-

Edge chatter: blade warped — replace or try a stiffer core.

-

Rapid wear: material incompatibility with inks/solvents — switch to polyurethane.

Change one variable at a time and log results; systematic tweaks beat guesswork.

Budgeting and cost-per-print reality

Account for more than sticker price. Durable urethane that lasts longer reduces re-bevel labor, fewer rejects, and fewer screen repairs. Ask suppliers for estimated life hours under a simulated workload; compare that to cheap alternatives. Often the true Best screen printing squeegee is the one that lowers your cost-per-print across months, not the cheapest option per inch.

Quick checklist — pick the best squeegee for a new job

-

Identify substrate and mesh count.

-

Determine desired deposit (thin, medium, heavy).

-

Choose material (polyurethane for production, neoprene for budget, rubber for hobby).

-

Choose durometer (70 general; 80+ detail; multi-duro for heavy deposits).

-

Pick bevel (45° general; steeper for fine detail).

-

Run sample prints and score results for coverage, detail, and wear.

Following this checklist will get you to your Best screen printing squeegee faster and with less waste.

Final thought — small investment, big return

A good squeegee is one of the easiest ways to upgrade print quality without changing presses or inks. Pick a blade that matches your day-to-day needs, keep a small set for specialty jobs, and prioritize urethane if you run solvent-based inks or long production cycles. Do that and your next runs will feel smoother, your halftones will pop, and your customers will notice the difference — that’s the real value of choosing the Best screen printing squeegee.

Pre:Why choosing the right squeegee blade matters — and how squeegee rubber changes prints

Next:Why the right nylon membrane syringe filter matters for every lab

Tags: