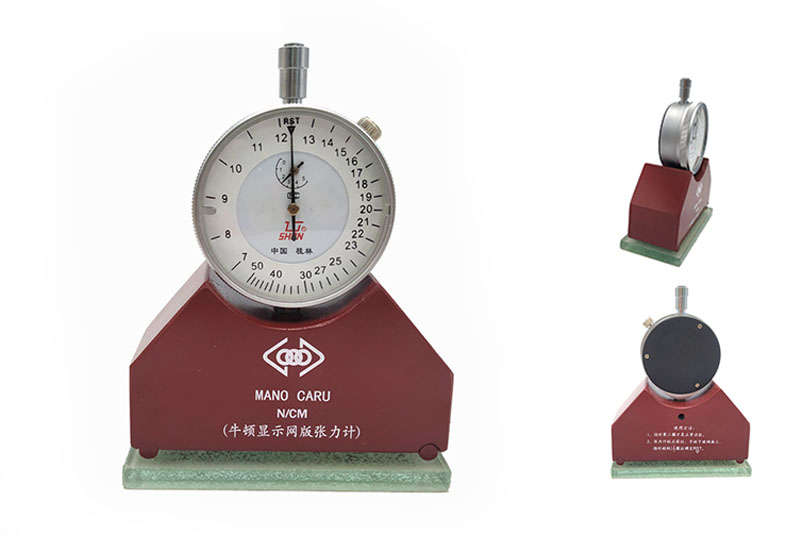

Tensiometer: Your Screen Printing Game-Changer

In the world of screen printing, few things are as crucial as proper screen tension. Its the difference between smudged, inconsistent prints and crisp, punchy designs that pop with every pass of the squeegee. Thats where the tensiometer entersnot just a g

In the world of screen printing, few things are as crucial as proper screen tension. It’s the difference between smudged, inconsistent prints and crisp, punchy designs that pop with every pass of the squeegee. That’s where the tensiometer enters—not just a gadget, but a precision companion that empowers printers to dial in perfect tension, job after job.

Why Screen Tension Matters More Than You Think

In screen printing, mesh tension affects everything—from ink deposit to registration stability. A screen stretched too loosely allows fabric to flex during printing, leading to blurred edges or misalignment. Too tight, and you risk tearing mesh or overworking your frames.

The tensiometer eliminates guesswork. It delivers accurate, measurable values—usually in Newtons per centimeter—so that tension is consistent, repeatable, and matched across all your screens. Once tension is dialed in, your prints follow suit, giving you reliable registration and clean detail every time.

Precision Built for Demanding Environments

Top-tier tensiometer units are constructed to last. A sturdy metal housing—often aluminum or steel—protects a precision movement, guaranteeing accuracy even in a busy print shop. Many offer calibration certificates and rugged casings to stand up to daily testing. That durability means you’re investing in more than just a tool—you’re investing in consistency that lasts.

Think about it: a bent needle or loose spring could throw off an entire production run. A quality tensiometer keeps your calibration solid and your output sharp.

Simple, Yet Essential Workflow Integration

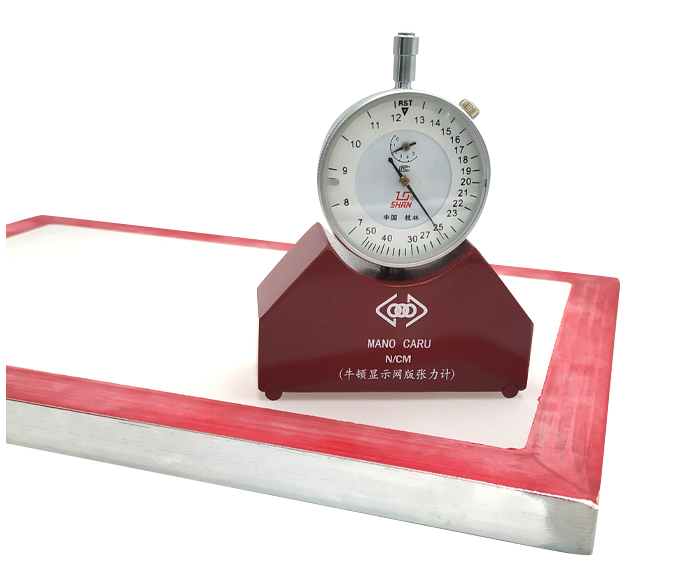

Using a tensiometer fits smoothly into your prep routine. Here’s how it works:

-

Mount your screen as usual.

-

Gently touch the reading rod to the mesh.

-

Rotate 90 degrees to measure both warp and weft tension.

-

Adjust your stretcher until both readings align within a narrow band—often within a couple of Newtons of each other.

That straightforward process delivers enormous payoff. Better tension means prints peel off the frame cleanly, maintain consistent ink thickness, and last longer through repeated runs.

Consistency Across Your Entire Shop

A standout feature of a solid tensiometer is repeatability. Whether you’re stretching one screen or fifty, the goal is uniform tension. When tension settings are standard—say, 25 N/cm across the board—your production becomes genuinely scalable. Every screen behaves the same, every print matches, and setup consistency skyrockets.

It’s a mark of professionalism that’s felt, not just seen.

User Wisdom: Real Printers, Real Benefits

Screen printers consistently praise how a tensiometer becomes an indispensable ally in the shop. One shop manager shared, “Almost all registration issues stem from uneven tension. Once we started calibrating with a tensiometer, prints instantly intensified and stabilized.”

Another seasoned operator noted that using even entry-level tension meters offered more reliable outcomes than guesswork based on feel—plus saved precious production time and wasted frames.

How to Choose the Right Tensiometer for Your Shop

Selecting a tensiometer isn’t complicated, but a few things matter:

-

Measurement Range: Opt for a model covering at least 0–130 N/cm—that fits most mesh setups.

-

Accuracy & Calibration: +/-1% accuracy with a certificate is ideal.

-

Durable Build: Look for solid metal housing and protective case if your environment demands resilience.

-

Ease of Use: A dial or digital display with clear increments makes calibration quick.

-

Reliability: Springs wear out; prefer a meter with minimal mechanical complexity or user-replaceable parts.

Investing Pays Off, Fast

A tensiometer isn’t a luxury—it’s a cost-saver. Better tension means:

-

Less waste: fewer botched screens, fewer off-register prints.

-

Faster setup: spend less time fiddling with film, exposures, or re-stretching.

-

Improved quality: cleaner halftones, smoother gradients, and sharper detail.

Even a single poorly tensioned screen can derail a run. A reliable tensiometer avoids that pain altogether.

Final Thoughts: Tension Is the Foundation of Great Prints

Every layer of screen printing relies on stability—and that starts with tension. A tensiometer isn’t just a measurement tool; it’s the guardian of clarity, consistency, and trust in your craft. From mesh to garment and job after job, it ensures your artistry stays sharp and dependable.

In short: if you’re committed to professional-quality prints, your tensiometer isn’t optional—it’s essential.

Tensiometer

Pre:Aluminum Scoop Coater: The Essential Tool for Precision in Screen Printing

Tags: