Aluminum Scoop Coater: The Essential Tool for Precision in Screen Printing

In the world of screen printing, achieving consistent and high-quality results hinges on the tools you use. One such indispensable tool is the aluminum scoop coater . Whether youre a seasoned professional or a hobbyist, understanding the importance and fu

In the world of screen printing, achieving consistent and high-quality results hinges on the tools you use. One such indispensable tool is the aluminum scoop coater. Whether you're a seasoned professional or a hobbyist, understanding the importance and functionality of this tool can elevate your printing projects to new heights.

What is an Aluminum Scoop Coater?

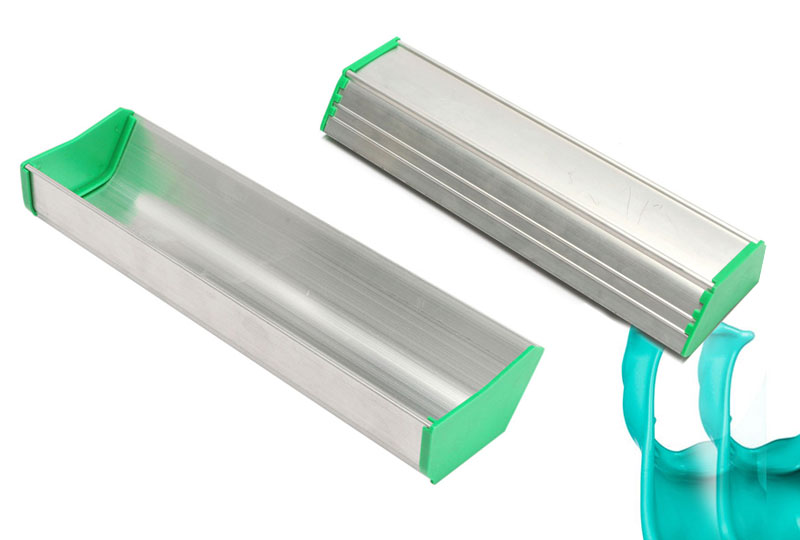

An aluminum scoop coater is a specialized tool designed for applying emulsion evenly onto screen printing frames. Made from durable aluminum, it offers a lightweight yet sturdy construction that ensures longevity and consistent performance. The dual-edged design typically features a sharp edge for fine coats and a rounded edge for thicker applications, catering to various mesh counts and emulsion types.

Why Choose an Aluminum Scoop Coater?

1. Durability and Lightweight Design

The primary advantage of an aluminum scoop coater lies in its construction. Aluminum is known for its strength-to-weight ratio, making the coater both durable and easy to handle. Unlike plastic alternatives, aluminum scoop coaters are less prone to warping and can withstand the rigors of daily use in a screen printing environment.

2. Even and Consistent Coating

Achieving a uniform emulsion layer is crucial for producing high-quality prints. The design of the aluminum scoop coater allows for smooth application, reducing the chances of streaks or uneven thickness. This consistency is vital for maintaining the integrity of your designs and ensuring sharp, clear prints.

3. Versatility Across Mesh Counts

Different printing projects require different mesh counts. An aluminum scoop coater's dual-edge design enables users to switch between sharp and rounded edges, accommodating various mesh counts and emulsion types. This versatility makes it a one-stop solution for all your coating needs.

4. Ease of Cleaning and Maintenance

Maintaining your tools is essential for their longevity and performance. Aluminum scoop coaters are relatively easy to clean, especially when compared to their plastic counterparts. Regular cleaning ensures that no residual emulsion affects future applications and that the tool remains in optimal condition.

Selecting the Right Aluminum Scoop Coater

When choosing an aluminum scoop coater, consider the following factors:

-

Size: Ensure the coater is approximately 2–3 inches narrower than your screen's inner width for optimal coverage.

-

Edge Design: Depending on your projects, select a coater with appropriate edge designs (sharp for fine coats, rounded for thicker applications).

-

Handle Design: A comfortable grip can reduce hand fatigue during prolonged use.

-

End Caps: Some models come with end caps to prevent emulsion spillage and facilitate easier handling.

Recommended Aluminum Scoop Coaters

While specific product recommendations can vary, it's advisable to look for reputable brands known for their quality and customer service. Ensure that the coater meets the size and design specifications suitable for your printing needs.

Tips for Using an Aluminum Scoop Coater

To maximize the effectiveness of your aluminum scoop coater:

-

Load the Coater Properly: Fill the coater halfway with emulsion to prevent overflow.

-

Angle the Screen Correctly: Hold the screen at a slight angle to allow gravity to assist in the coating process.

-

Apply Even Pressure: Maintain consistent pressure while moving the coater across the screen to ensure uniform coverage.

-

Clean After Use: Immediately clean the coater after each use to prevent emulsion from drying and causing blockages.

Conclusion

The aluminum scoop coater is more than just a tool; it's an investment in the quality and consistency of your screen printing projects. By understanding its features, benefits, and proper usage, you can enhance your printing outcomes and streamline your workflow. Remember, the right tools lead to the best results.

Scoop coaterPre:Screen Printing Emulsion Scoop Coater: Precision Starts Here

Tags: