Scoop Coater: Your Secret Weapon for Consistent, High-Quality Screen Printing

In the world of screen printing, every tool plays a vital role in shaping the final outcome. Among these, the Scoop Coater stands out as one of the most critical instruments for professionals and beginners alike. It may look simple, but its design, precis

In the world of screen printing, every tool plays a vital role in shaping the final outcome. Among these, the Scoop Coater stands out as one of the most critical instruments for professionals and beginners alike. It may look simple, but its design, precision, and ease of use make it the cornerstone of producing high-quality stencils. Whether you are running a large print shop or starting from a small studio, investing in the right scoop coater can be the difference between a flawless print and one riddled with imperfections.

Why the Scoop Coater Matters in Screen Printing

At its core, the scoop coater is designed to apply a smooth and even layer of emulsion to a screen. The emulsion is what blocks out areas of the screen during printing, allowing only the desired design to transfer onto the printing surface. An uneven layer can cause ink leakage, blurred edges, or weak stencils that break down quickly. With a high-quality Scoop Coater, the emulsion coating is applied uniformly, resulting in durable screens and sharp, vibrant prints.

For printers who value consistency, this tool is non-negotiable. It ensures that every screen, regardless of size, receives the same professional treatment. When paired with proper exposure techniques, it sets the stage for accurate, detailed, and long-lasting prints.

Features That Define a Quality Scoop Coater

Not all scoop coaters are created equal. When considering which one to purchase, professionals often look for several defining characteristics:

-

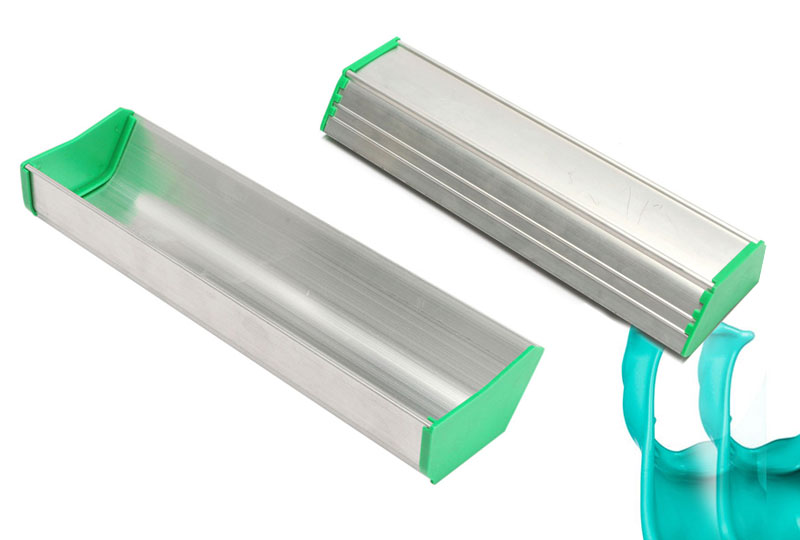

Durability – Made from strong aluminum, a good scoop coater will resist bending or warping over time. This ensures the edge stays straight and the coating remains smooth after repeated use.

-

Dual-Edge Design – Many models include two edges: a sharp edge for thin coats and a rounded edge for thicker coats. This versatility makes it easy to adapt to different printing requirements.

-

Ergonomic Grip – A comfortable grip reduces strain during coating, especially when working with large screens.

-

Easy Cleaning – Since emulsions can harden quickly, a smooth and easy-to-clean surface is essential for long-term usability.

When all these factors come together, the Scoop Coater becomes a tool that is not only functional but also reliable for years of screen printing projects.

How to Use a Scoop Coater Correctly

Even the best tool needs proper technique. The correct use of a scoop coater determines how well the emulsion layer will set on the mesh. Here are the key steps to mastering its use:

-

Prepare the Screen: Make sure the screen is degreased, dried, and free from dust or residue.

-

Load the Emulsion: Pour the emulsion into the trough of the scoop coater, being careful not to overfill.

-

Angle and Pressure: Hold the scoop coater at a consistent angle—usually around 45 degrees. Apply steady, even pressure as you move upward across the screen.

-

Consistency: Coat both sides of the screen if necessary, ensuring the emulsion layer is balanced.

-

Drying: Allow the screen to dry in a dark, dust-free environment before exposure.

By following these steps, printers maximize the effectiveness of their Scoop Coater and ensure their screens are prepped for high-quality results.

Advantages for Professionals and Beginners

One of the most impressive qualities of the scoop coater is its versatility. Beginners find it easy to learn and manage, while professionals rely on it for precision and efficiency.

For newcomers, the scoop coater removes much of the guesswork from screen preparation. Instead of struggling with uneven emulsion layers, they can quickly learn the right technique and achieve professional results. For experienced printers, it speeds up production, reduces waste, and guarantees consistent outcomes, job after job.

Choosing the Right Size Scoop Coater

Scoop coaters come in different lengths to match the size of the screen being used. A good rule of thumb is to select a scoop coater that is slightly smaller than the inner dimensions of the frame. This allows the emulsion to be applied evenly across the mesh without spillage or gaps.

For example:

-

Small coaters work well with compact screens used in hobby projects or small print runs.

-

Medium sizes are suitable for mid-range screens often used in commercial shops.

-

Large coaters are designed for oversized frames, ensuring wide surfaces are coated efficiently in one motion.

By matching the coater size to the frame, printers make their work faster, cleaner, and more precise.

The Scoop Coater as a Long-Term Investment

When viewed as part of the bigger picture of screen printing, the scoop coater is not a one-time accessory but a long-term investment. Its role in ensuring durability of screens, reducing emulsion waste, and enhancing the clarity of prints makes it invaluable. For businesses, this translates to better customer satisfaction and improved profit margins. For hobbyists, it provides the confidence to explore more complex designs without worrying about technical failures.

Care and Maintenance Tips

To keep a scoop coater functioning at its best, simple maintenance is key:

-

Clean immediately after use to prevent hardened emulsion from sticking.

-

Store in a dry, safe place where it won’t be bent or scratched.

-

Inspect regularly for damage to the edges, since even minor imperfections can affect coating quality.

With proper care, a good Scoop Coater will last many years and provide reliable results throughout its lifespan.

Why Every Print Shop Needs a Scoop Coater

Whether you are printing custom t-shirts, posters, or promotional products, the scoop coater is the foundation of your process. It ensures that the stencil, which determines the sharpness and clarity of the print, is perfect from the very beginning. Without it, even the most advanced printing presses or high-quality inks cannot achieve their full potential.

For those who take screen printing seriously, skipping this tool is not an option. It provides the control, efficiency, and consistency required to succeed in a competitive industry.

Final Thoughts

The Scoop Coater may not be the flashiest tool in the screen printing studio, but it is undeniably one of the most important. Its ability to deliver smooth, even emulsion layers makes it essential for both beginners and experienced professionals. By investing in a durable, well-designed scoop coater, printers ensure the quality of their work, save time, and reduce material waste.

From small custom projects to large-scale production, the scoop coater is a reliable companion that helps bring designs to life with clarity and precision. It is more than just a tool—it is the first step toward professional, eye-catching screen prints that stand the test of time.

Pre:Plastic Ink Knife: The Essential Tool for Cleaner, Smoother Printing

Tags: