Why investing in dry sift screens south africa changes how you capture value from trim

Choosing the right dry sift screens south africa set is both a technical and business decision. Start with a modest, well-specified cascade, practice your technique (freeze, gentle agitation), and document yields and purity by strain.

If you’re turning trim and small buds into concentrates, sourcing the right dry sift screens south africa suppliers and kits is the single upgrade that improves both product quality and profitability. Good screens separate intact trichome heads from leaf and stem with minimal breakage, producing clean kief that presses better and yields more rosin. Whether you’re a hobbyist or a small processor, a well-chosen set of screens pays back almost immediately in better concentrates and less post-processing.

What dry sift screens south africa actually are — formats and spec basics

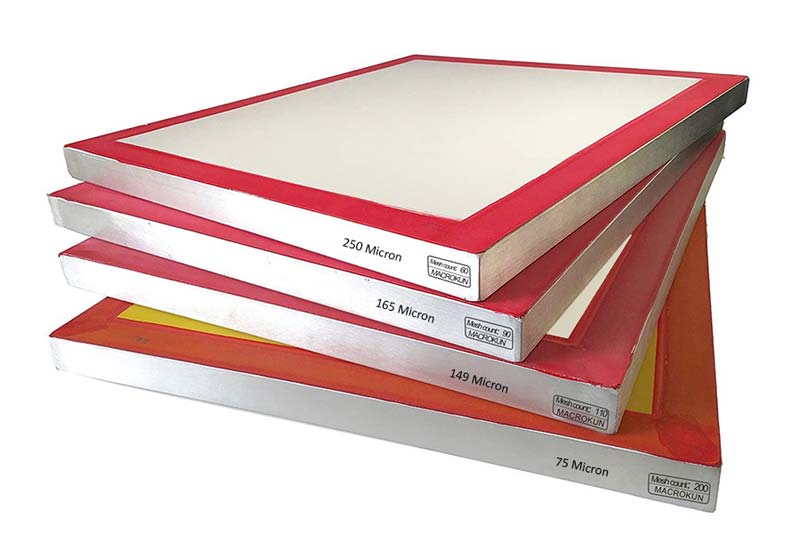

At the simplest level, dry sift screens south africa are framed meshes (or press screens) designed to sieve dried, cured plant material so trichomes fall through while larger plant matter stays above. They’re sold as single panels, multi-screen cascades, or fitted press/rosin screens. Specifications you’ll see are mesh count (lines per inch), micron equivalents, frame size (20×24, 12×16, 40 cm, etc.), and frame material (aluminum, wood, or reinforced plastic). For buyers in South Africa, choose suppliers that publish the micron equivalents clearly — this makes comparison easy and avoids surprises at first use.

How to choose micron and mesh — balancing purity and yield

Choosing the right dry sift screens south africa set is largely a tradeoff between yield and purity:

-

Coarser screens (e.g., ~150–250 µm) give higher yield but more plant contaminants — good for mass collection where weight matters.

-

Mid-range screens (≈70–120 µm) are the sweet spot for many users who want a clean sift with reasonable yield.

-

Fine screens (≤25–50 µm) deliver the purest product but trap more material and require careful handling to avoid clogging.

If you’re starting, buy a 3-screen or 4-screen cascade (coarse → medium → fine) so you can grade your material and decide which fraction to press or sell. Many dry sift screens south africa listings bundle these combinations to make the decision easier.

Material choices — stainless, polyester and the frame tech that matters

Not all meshes behave the same. Stainless steel meshes are durable and easy to clean, while monofilament polyester/nylon meshes can be gentler on trichomes and cost-effective for certain workloads. The frame matters too: aluminum frames resist warping and work well with press rigs; wooden frames are cheap and fine for occasional hand sifting. When you evaluate dry sift screens south africa, pick frames and mesh material that match your throughput and cleaning routine — rugged frames reduce downtime on busy days.

Single-panel sifting vs multi-layer cascades — practical workflows

Hobbyists often start with a single dry sift screens south africa panel and hand-rub or shake material over it. That’s good for learning. For consistent grading and higher throughput, move to stacked or cascaded systems that capture several fractions at once — you get coarse kief for certain products and fine kief for premium pressing. If you plan to scale, look for modular systems and screens sized to common presses (e.g., 20×24) so your equipment investments remain flexible.

Techniques that protect trichome integrity — speed, freeze, and gentle agitation

Technique is critical when using dry sift screens south africa: freezing plant material briefly before sifting reduces brittleness and aids separation; avoid over-grinding because smashed trichomes pass through finer screens and reduce final quality; and use gentle, rhythmic agitation or light rubbing rather than aggressive shaking. For larger batches, low-speed tumblers or vibration tables paired with a cascade of screens greatly improve throughput without sacrificing purity.

Cleaning and maintenance — keep your screens performing

Screens work best when they’re clean and evenly tensioned. After each run, remove loose debris with gentle brushing or compressed air; stainless screens can be cleaned with mild solvents or ultrasonic baths where legal and safe. Inspect frames for sag or tears — a warped dry sift screens south africa panel produces inconsistent results and will cost you purity. Keep spare meshes on hand; replacing a worn screen is cheaper than salvaging a ruined batch.

Local buying tips — sourcing dry sift screens in South Africa

South Africa has both handcrafted local makers and import options. When shopping for dry sift screens south africa, check these practical points:

-

Micron and mesh equivalency — ask the seller to confirm micron ratings rather than only mesh numbers.

-

Frame dimensions — ensure frames fit your tumblers, press, or bench space.

-

Stock availability — local stock means faster replacement; imported sets may work but factor shipping and customs.

-

Sample packs — good sellers offer starter packs of 3–4 meshes so you can test before scaling.

Local makers often offer custom sizes and quick replacements, while reputable importers list standard sets that ship to South Africa — both options are viable depending on urgency and budget.

How to test screens on arrival — a quick validation routine

Don’t assume all screens are identical. For every new dry sift screens south africa purchase, validate quickly:

-

Visual & tactile check — confirm mesh uniformity and frame straightness.

-

Test run — sift a small, known-weight sample and weigh the output to get initial yield data.

-

Purity check — examine the sift under magnification or through a simple manual inspection for plant debris.

Log the results — a short acceptance test prevents surprises and helps you standardize which microns work best for each strain.

Turning sift fractions into products — pressing and selling strategies

The economic power of dry sift screens south africa comes when you turn graded kief into value: pressing the finest fraction yields premium hash or rosin; coarser fractions can be sold as affordable concentrates or blended. For rosin, prioritize the finest clean fractions to minimize plant particulates that create off-flavors or obstruct yields. Some processors create multiple SKUs by combining graded fractions — a smart route to maximizing revenue from the same harvest.

Scaling: small startup to light manufacturing

If you’re scaling beyond hand sifting, invest in a small tumble-sifter, multiple frame sets, and a small press station. Automating agitation and having dedicated frames for different microns speeds throughput and reduces operator fatigue. When you systemize with reliable dry sift screens south africa gear and SOPs for freezing, agitation and pressing, you can grow volumes while maintaining product consistency.

Buying checklist — what to ask before you buy

When you’re ready to buy dry sift screens south africa, ask sellers for:

-

Micron ratings and mesh ↔ micron conversion.

-

Frame material and true usable area (not just external dims).

-

Stock/lead time and shipping to your location.

-

Replacement policy and spare mesh availability.

-

Any recommended SOPs or starter kits for local strains.

A short conversation with the supplier will usually clarify whether their product matches your needs; good sellers are happy to recommend a starter kit.

Final thought — pick the right screens once and scale with confidence

Choosing the right dry sift screens south africa set is both a technical and business decision. Start with a modest, well-specified cascade, practice your technique (freeze, gentle agitation), and document yields and purity by strain. That disciplined approach converts a consumable purchase into a predictable production asset — and it’s the fastest way to turn trim and trichomes into high-value concentrates.

Dry Sift Screen

Pre:Why kief sifting screens should be the first tool in your hash workflow

Next:none

Tags: