Why the 70 durometer squeegee is the most practical blade for many shops

If your shop runs mixed workloads and you want to minimize blade juggling, standardizing on a 70 durometer squeegee (with one or two complementary blades) is the most practical path.

If you keep one blade in stock and want the fewest surprises across garments, signage and poster work, a 70 durometer squeegee is the sensible default. It sits squarely between soft blades that over-deposit and hard blades that under-deposit, giving reliable ink laydown, decent detail and forgiving behaviour on slightly uneven substrates. For mixed shops — where operators run both heavy underbases and finer spot colours — having a trusted 70A blade repeatedly reduces re-runs and setup tinkering.

What a 70 durometer squeegee is (and what it isn’t)

A 70 durometer squeegee refers to the hardness of the blade (Shore A scale ≈ 70). That number describes how rigid the elastomer is: 70A is stiff enough to shear ink cleanly through mesh without “rolling” on the print, yet soft enough to conform slightly to screen contour so you don’t lose ink contact on uneven areas. It isn’t the softest (that would be 60A) nor the hardest (80–90A); it’s intentionally in the middle so one blade can cover many jobs without constant swapping.

Why many printers choose a 70 durometer squeegee for general work

Practically speaking, a 70 durometer squeegee gives you the best of both worlds. Shops report fewer ghosting issues, predictable ink deposit for both plastisol and many water-based systems, and easier handling on manual presses. When operators must choose between throughput and detail, 70A rarely needs to be traded out on small jobs; that lowers downtime and training friction. Guides from established suppliers identify 70A as a common starting point for textile printing and general graphics.

Best use cases — when to reach for a 70 durometer squeegee

An ideal job for a 70 durometer squeegee includes:

-

Mid-mesh textile work (e.g., typical chest prints on T-shirts using mesh counts around 156–230).

-

Spot colour printing where you need both reasonable opacity and some fine line control.

-

Short to medium production runs where operators prefer to minimize blade changes.

-

Shops that run mixed substrates — the 70A blade adapts well when you switch from cotton to polyester blends.

If the job is all heavy whites on low mesh or deep flood fills, you might use a softer blade; if it’s ultra-fine halftones on very high mesh, you might step up to 80–90A. But for most “everyday” work, 70A is a reliable compromise.

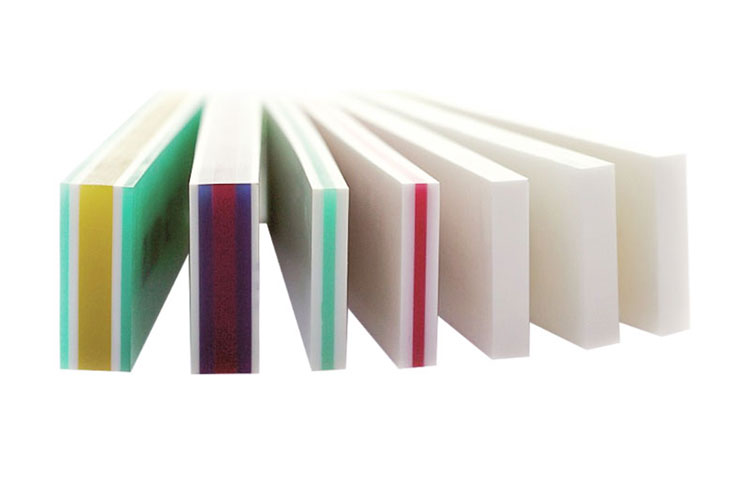

Material and construction — why polyurethane blades at 70A are preferred

Most professional 70A blades are polyurethane because that polymer offers excellent wear resistance, solvent stability and edge retention. A quality 70A polyurethane blade resists swelling with solvents, sharpens predictably and holds durometer under heat — all traits that lead to consistent deposition over long runs. Triple or dual-durometer constructions often pair a 70A working edge with a harder spine for stability, combining flexibility at the tip with rigidity behind it. This engineered approach improves longevity while preserving the 70A feel at the print edge.

Edge profile and bevel — tune the 70 durometer squeegee for the job

How you bevel a 70 durometer squeegee affects ink shear and detail. Common profiles:

-

Square edge — fuller ink deposit, easier for heavy fills.

-

45° bevel — versatile everyday profile; good balance of deposit and release.

-

60°+ bevel — sharper contact, better for halftones and fine detail with higher mesh counts.

A 70A blade with a 45° bevel is the classic shop workhorse; if you need crisper linework, a steeper bevel or a harder backing (70/90/70) will help without abandoning the 70A working edge.

Matching mesh, ink and the 70 durometer squeegee — practical pairings

Don’t pick a blade in isolation. Typical pairings that work well in the field:

-

70A + 156–230 mesh for standard garment printing and spot colours.

-

70A + water-based inks when you want moderate deposit and good hand (softer feel).

-

70A + plastisol for balanced opacity without overly thick underbases (for heavy whites you may prefer 60A or triple-duro combos).

These pairings are widely recommended by suppliers and trainers because they yield predictable film thickness across common meshes and inks. If you’re unsure, start with a 70A blade and a mid-mesh test print; adjust from there.

Maintenance and sharpening — keep a 70 durometer squeegee working longer

A well-maintained 70 durometer squeegee lasts longer and prints more consistently. Practical tips:

-

Store blades flat and away from solvents and heat to avoid warping.

-

Rotate blades to even wear across the edge.

-

Re-bevel lightly with a sharp razor when the edge softens — polyurethane re-sharps cleanly.

-

Replace before severe nicks appear; a damaged 70A edge ruins registration and micro-detail.

Following these steps extends blade life and keeps your prints predictable across runs.

Quick tests to confirm a 70 durometer squeegee fits your job

Before bulk ordering, run three quick in-house tests with a candidate 70A blade:

-

Coverage test: single-pass flood + print to check opacity on your mesh and ink.

-

Detail test: print fine linework or halftone patch to evaluate dot gain.

-

Durability test: run a simulated short production (100–200 pulls) to see edge wear and solvent interaction.

If those tests pass for your substrate and mesh, the 70 durometer squeegee is a safe standardized choice for routine use. Printers Edge

Buying guide — what to ask suppliers about 70A blades

When sourcing a 70 durometer squeegee, ask for:

-

Exact durometer tolerance and polymer formulation (polyurethane grade).

-

Available bevel angles and whether the blade is single/dual/triple durometer.

-

Edge retention data and recommended inks/cleaners.

-

Sample or short-length policy so you can test before bulk buy.

Suppliers who publish durometer tolerance, bevel options and sample policies make validation fast and safe.

Stocking strategy and cost-per-print considerations

Standardize on a small set: one 70A general blade (45°), one softer blade for heavy fills, and one harder or multi-duro blade for fine detail. Keeping a few 70A blades in ready stock avoids downtime and minimizes changeovers. Because 70A blades are versatile, the cost-per-print typically drops — you change blades less often and reduce press setup time. Track blade life across jobs to refine reorder points.

Troubleshooting: common prints problems and how a 70A blade helps

-

Blurry halftones: often the blade is too soft or edge is rounded — step up bevel or use a harder backing.

-

Too low deposit: edge is too hard or bevel too steep — the 70A working edge is flexible enough to increase deposit vs 80–90A.

-

Edge chatter: check for warped or damaged blade — a quality 70A polyurethane blade resists chatter if kept flat and clean.

Use single-variable testing (change only bevel or durometer) to identify the fix fast.

Final recommendation — when to standardize on a 70 durometer squeegee

If your shop runs mixed workloads and you want to minimize blade juggling, standardizing on a 70 durometer squeegee (with one or two complementary blades) is the most practical path. It handles a wide range of inks and meshes, sharpens predictably, and is available in single, dual and triple durometer constructions for extended life. Start with sample lengths, run the three quick tests above, and lock in the blade that produced the best balance of deposit and detail for your most common jobs. You’ll reduce changeovers, make training simpler, and keep prints consistent — and that’s the point of choosing a dependable 70A workhorse.

squeegee suppliesPre:Why the right nylon membrane syringe filter matters for every lab

Next:Why choosing the right amazon screen printing squeegee suppliers matters for every shop

Tags: