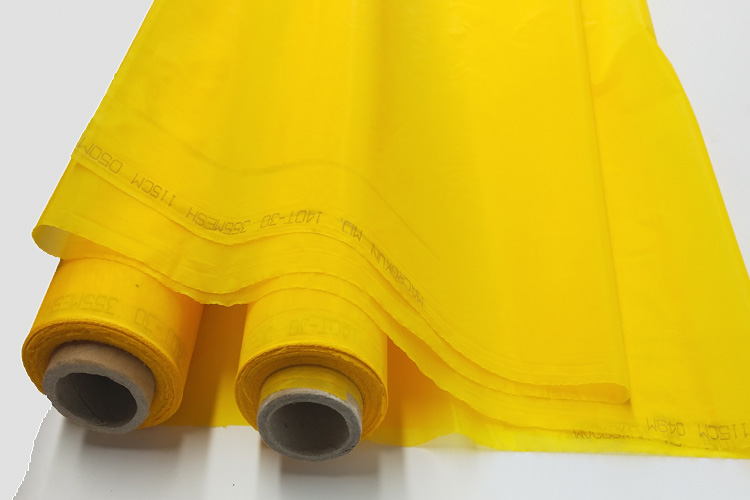

Unlock Superior Filtration Efficiency with Our Premium Rotary Screen Mesh

If you are seeking a reliable, efficient, and long-lasting filtration solution, our rotary screen mesh is the answer. Engineered for precision, strength, and durability, it offers unmatched performance across a wide range of industries.

In the world of industrial filtration and separation, precision, durability, and efficiency are non-negotiable. When you require high-performance solutions that stand up to rigorous demands, rotary screen mesh proves to be an unbeatable choice. As industries continue to seek reliable and cost-effective methods for solid-liquid separation, the demand for quality rotary screen mesh products has skyrocketed.

In this article, we’ll explore the critical role rotary screen mesh plays across various industries, its key features, and why our premium offerings should be your first choice for boosting filtration performance. Whether you are in wastewater treatment, mining, food processing, or paper manufacturing, understanding the benefits of investing in top-tier rotary screen mesh will transform your operations.

What Is Rotary Screen Mesh?

Rotary screen mesh refers to a cylindrical screen system where a rotating drum is used to separate solids from liquids through a fine mesh surface. It is an essential component in rotary drum screens, which are used extensively for applications where continuous filtration and high solids removal efficiency are needed.

The mesh on the rotary screen is specifically designed to capture particles of varying sizes while allowing fluids to pass through effortlessly. The rotating motion prevents clogging and enables self-cleaning, making it a low-maintenance and highly efficient filtration option.

Why Rotary Screen Mesh is Critical to Industrial Processes

Across industries, managing waste streams, clarifying liquids, and ensuring product purity are vital operational goals. Choosing the right rotary screen mesh can impact:

-

Filtration Quality: Effective separation of solids ensures smoother downstream processes.

-

Operational Efficiency: Minimized clogging and downtime increase productivity.

-

Cost Savings: Durable mesh reduces the need for frequent replacements and costly maintenance.

Companies that prioritize high-grade rotary screen mesh experience enhanced throughput, longer equipment lifespans, and better overall operational efficiency.

Features of High-Quality Rotary Screen Mesh

When investing in rotary screen mesh, it's important to focus on several key features:

1. Precision Openings

Our rotary screen mesh is engineered with uniform and precise openings, allowing for accurate particle separation according to your specific operational needs.

2. High-Strength Materials

We use only premium materials such as stainless steel and specialized polymers to ensure the mesh can withstand mechanical stress, chemical exposure, and prolonged use.

3. Corrosion and Wear Resistance

The robust construction of our rotary screen mesh ensures outstanding resistance to corrosion and wear, even in the harshest environments like saltwater treatment or chemical processing plants.

4. Easy Maintenance

Designed for minimal clogging and effortless cleaning, our mesh dramatically reduces maintenance time and operational interruptions.

5. Customization Options

Every application is different. That’s why we offer customized rotary screen mesh in various diameters, lengths, and aperture sizes to perfectly suit your system requirements.

Top Applications of Rotary Screen Mesh

Rotary screen mesh is a versatile solution that finds use in a variety of industries, including:

1. Wastewater Treatment

In municipal and industrial water treatment plants, rotary screen mesh helps in the efficient removal of solids from incoming wastewater, improving overall treatment performance.

2. Food and Beverage Processing

Food production facilities use rotary screen mesh to separate solids from liquids, ensuring product purity and adherence to sanitary standards.

3. Mining and Quarrying

The mining industry relies on heavy-duty rotary screen mesh to separate valuable minerals from slurry and tailings during extraction and processing.

4. Paper and Pulp Industry

Pulp processing plants use fine rotary screen mesh to remove contaminants and fibers, enhancing product quality.

5. Agriculture

In agricultural settings, rotary screen mesh assists in the processing of grains and separation of organic waste, leading to better product quality and waste management.

Benefits of Choosing Our Rotary Screen Mesh

At [Your Company Name], we take pride in offering rotary screen mesh that delivers unparalleled performance. Here’s why customers consistently choose us:

1. Superior Quality

Each mesh is manufactured under strict quality controls using premium-grade materials. We guarantee that our rotary screen mesh will deliver lasting performance and reliability.

2. Custom Engineering

Our team works closely with clients to design custom solutions, ensuring the mesh fits seamlessly into your existing systems without expensive modifications.

3. Competitive Pricing

We offer market-leading rotary screen mesh at competitive prices without compromising on quality, providing excellent value for your investment.

4. Outstanding Customer Support

From consultation to after-sales service, our dedicated team is committed to helping you achieve optimal results with your filtration operations.

Choosing the Right Rotary Screen Mesh for Your Needs

Finding the perfect rotary screen mesh involves evaluating several factors:

-

Particle Size: Identify the particle size you need to separate to select the appropriate mesh opening.

-

Operating Conditions: Consider temperature, chemical exposure, and mechanical stresses your mesh will face.

-

Flow Rate: Ensure the mesh can handle your required throughput without compromising efficiency.

-

Durability Requirements: For heavy-duty applications, invest in stainless steel or other highly durable materials.

Our experts are ready to help you navigate these considerations and choose a rotary screen mesh solution tailored to your operational demands.

Customer Success Stories

Case Study 1: Municipal Water Treatment Plant A city water treatment plant struggling with frequent screen clogs upgraded to our stainless steel rotary screen mesh. They reported a 40% increase in throughput and a 60% reduction in maintenance costs within the first six months.

Case Study 2: Food Processing Facility A food processing company needed ultra-fine separation for their juice production line. After installing our custom-designed rotary screen mesh, they saw improved product clarity and reduced downtime due to clogging.

Conclusion: Invest in High-Performance Rotary Screen Mesh Today

If you are seeking a reliable, efficient, and long-lasting filtration solution, our rotary screen mesh is the answer. Engineered for precision, strength, and durability, it offers unmatched performance across a wide range of industries.

Don’t let substandard filtration systems hold back your productivity. Upgrade to our premium rotary screen mesh and experience the difference in quality and efficiency.

Screen Mesh Rotary Screen Mesh

Pre:Saati Screen Printing Mesh: Precision, Performance, and Consistency for Every Print

Next:Elevate Your Screen Printing with the Premium Yudu 110 Mesh Screen

Tags: