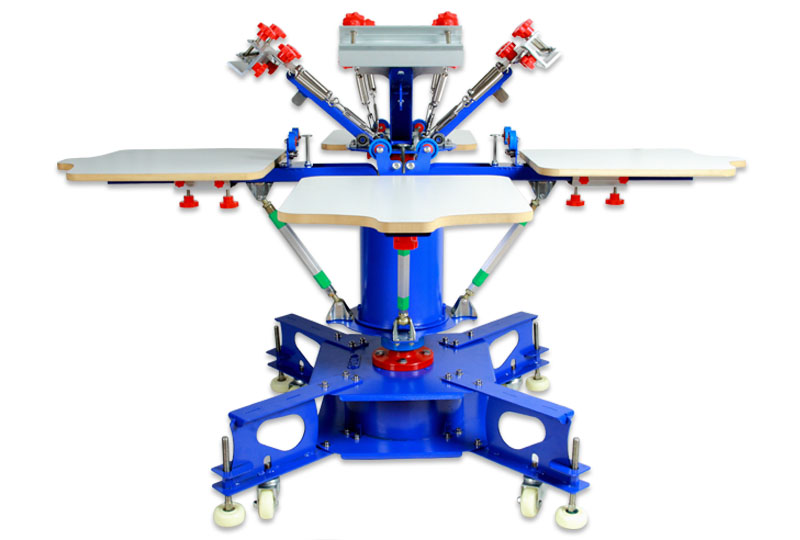

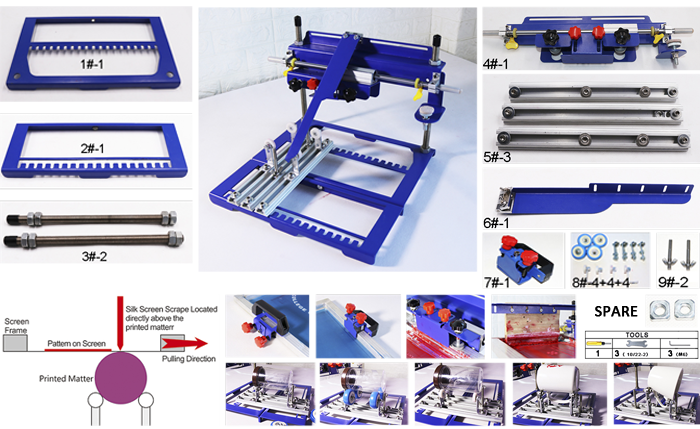

MK-QMH170 Atype curved screen printing machine

Description

Curved screen printing machine is mainly used for printing cylindrical type, cone type products; Such as a variety of plastic, glass, metal materials made of cylindrical, conical shape products, including wine bottles, medicine bottles, cosmetics bottles and other packaging bottles; Mugs, thermos mugs, beer mugs, red mugs, etc. Glass tube, pen ,ballpoint pen, fishing rod, bat and other small cylindrical products;

For cylindrical or conical type products, the printing surface has a large concave or convex, the printing surface has spots and other non-plane printing is not suitable for the machine.

| Product Code | 006591 |

| Product Name | MK-QMH170 Atype curved screen printing machine |

| HS Code | 8443192290 |

| Product Color | Blue |

| Machine Using Material | Steel plate |

| Machine Surface Treatment | Electrostatic spraying |

| Attachment Material | Stainless steel or zinc plating, nickel plating |

| Packing Quantity | 1 |

| Net Weight | 13lb |

| Gross Weight | 14lb |

| Packing Size | 16*12*4in |

| Packing Volume | 0.01m³ |

| Packing Material | Export carton |

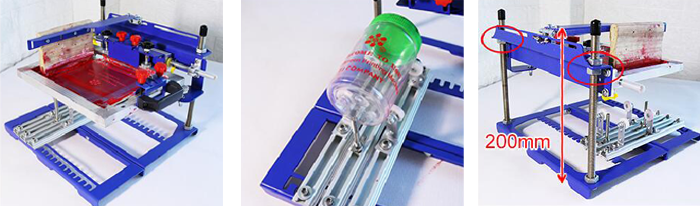

1. The machine adopts left and right push-pull structure.Installation parts can be adjusted as needed, it is suitable for left or right hand easy operation. Suitable for printing patterns with width less than 200mm; Length less than 150 mm ; Suitable for all kinds of screen plate with the outer diameter less than 260* 450mm and thickness less than 35mm.

2. The machine is positioned by adjusting the height of the rear main frame , the rear main beam according to the height of the substrate, by adjusting the stand column screw to adjust up and down .The upper and lower adjustment range is 200 mm.It can used for printing cylindrical and conical products with the diameter below 170 mm.

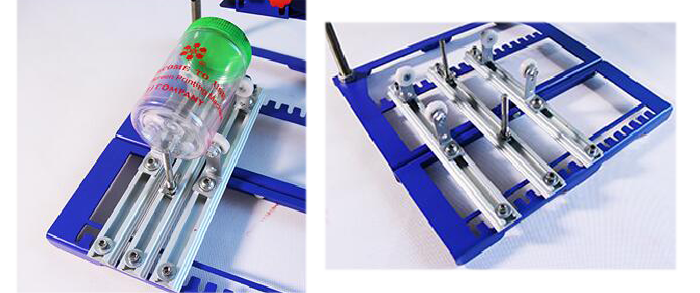

3. Substrate printing rack can move from left to right ,front to rear, three fixed aluminum bar in the bottom can be directly installed on the base, the aluminum bar base can move 290 mm from left to right ; Both sides aluminum alloy strips are substrate placement rack installation strip, the middle is substrate positioning rack installation strip. Three mounting bars can be moved around as needed. Lock position in the base front and rear 19 u-shaped holes (each hole spacing 15 mm), to ensure that the installation strip positioning accurate. Installation of aluminum bar movement: loosen the screws at both ends of the installation bar . Push the installation strip to the rear of the machine to the long hole of the strip, move the installation strip left and right until it is in a proper position, then pull the installation strip to the fixed U groove .Tighten the screws at both ends to complete the positioning.

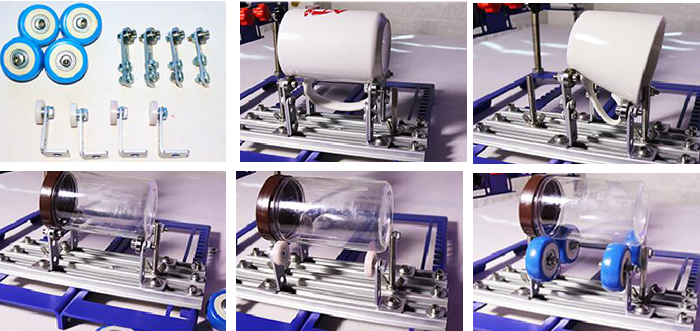

4. Adopts three sets of substrate to place rollers, respectively, metal bearing rollers (diameter of 19 mm); Nylon bearing roller (diameter 25 mm); Plastic bearing roller (diameter 50mm) can be changed according to the user's needs. Main frame and accessory frame can be installed with three rollers. The bearing mounting bracket is directly fixed in the hole of the aluminum bar mounting strip. It can move up to 160 mm according to the width of the substrate; 4 additional mounting frames, remove the bearings of the original mounting frame and fix the additional mounting frames on the main mounting frame directly with screws. It is mainly used for printing conical products. Additional mounting frame can move up and down 20 mm.

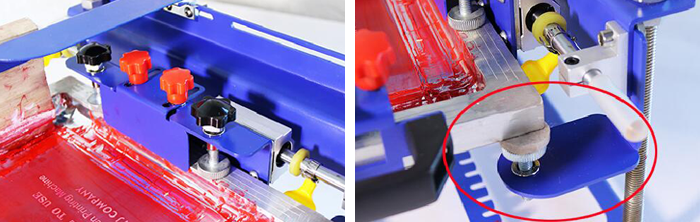

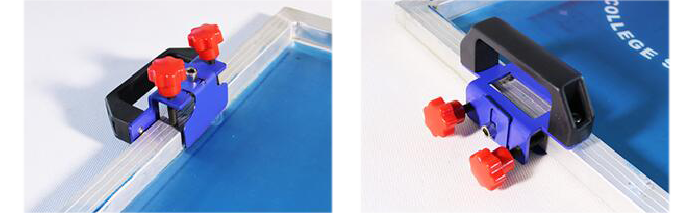

5. The installation of the screen plate is bidirectional fixed, the upper handle fixed screen frame; The baffle in the middle of the chuck is adjusted according to the width of the screen frame. After sticking to the inside of the frame, fix the two handles to fix the screen plate tightly. It can be applied to all kinds of screen plates with high, wide 10-35mm.

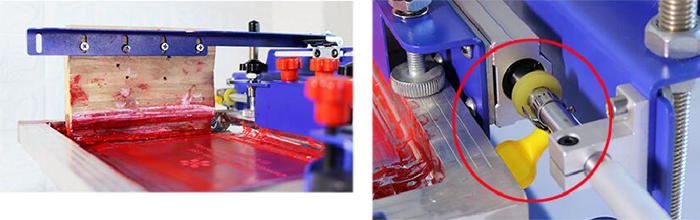

6. The screen plate support base is mainly used to support placement of the screen plate after printing , prevent the screen plate falling down when support by hand; The base can be adjusted up and down according to the thickness of the screen plate to suit the best support.

7. The screen frame with a special handle directly fixed on the screen frame, two installation methods, it can be installed in the upper part of the screen frame,it also can be installed on the side of the screen plate,it is easy to push and pull from left to right, the handle can be arbitrarily fixed in any part of the screen frame, the upper red handle and the front baffle fixed screen plate, to ensure that the screen plate firmly fixed on the handle. The handle fits various mesh frames within a thickness and width of 35 mm.

8. Squeegee rack is used for self-tapping wood handle squeegee, and it is suitable for the length of 200mm wood handle squeegee. The rack can be moved about 250mm according to the position of the pattern of the screen plate.

9. The screen plate movement distance positioning; Both sides of the optical axis are equipped with positioning rings and anti-impact rubber rings. The positioning rings are adjusted to the appropriate position according to the pattern size. Anti-impact apron can prevent the metal between the impact of abnormal sound, protect machine parts.

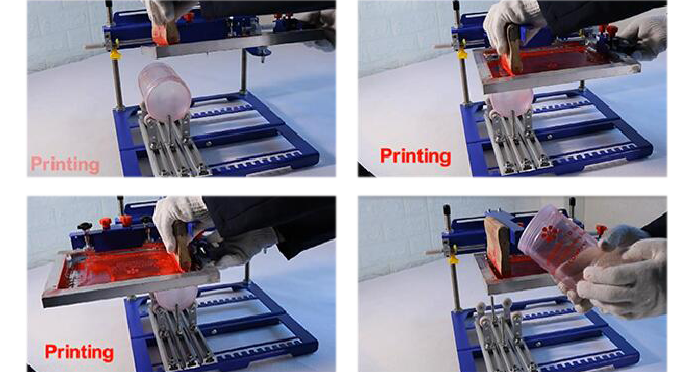

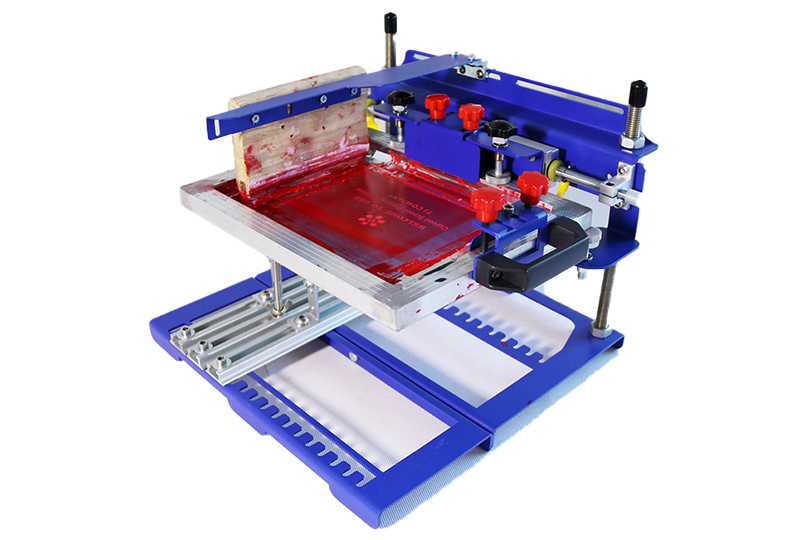

1. Install the screen plate and adjust the support seat under the screen plate to the basic level of the screen plate; Install screen frame pull handle;

2. Install the scraper and fix it at a distance of 1-2 cm from the pattern;

3. Adjust the position of the substrate printing frame and roller bearing, place the substrate, and the spacing between the top of the substrate and the screen plate is 1-3 mm; And make the substrate the top and the bottom of the scraper aligned;

4. Adjust the distance positioning knob of the screen plate according to the left and right dimensions of the pattern;

5. Put ink into the screen frame;

6. Press the scraper with the left hand (or right hand); Pull the handle with right hand (or left hand)on the screen frame to print.

How to Choose

Fast delivery, the shortest time delivery of goods

Safety First, Guaranteed and Diversified Payment

After-sales service to eliminate any concerns of customers

The product has a better price:

- We are a factory that produces screen printing. The more you buy, the cheaper your price.

- Product Number:

- Hs Code:59112000

Screen Printing Mesh6T(15 Mesh) to 165T(420 Mesh) |

Screen Printing Squeegee Bladescreen printing squeegee blades on sale at wholesale prices |

Screen Printing Squeegee Handle60 durometer , 70 durometer , 80 durometer , and 70/90/70 triple durometer. |

Screen printing Aluminum FrameScreen printing screens fulfill customers' needs and are welded for great mesh adhesion. |

Nylon Filter MeshNylon filter mesh with a wide range of mesh sizes and various types is widely used in the industries for liquid, gas and oil filtration. |

Screen Printing Machinewe have 1 color printing machine,2 color printing machine,4 color printing machine,6 color printing machine, 8 color printing machine |

Screen Printing MaterialsPrinting materials, printing equipment, printing accessories, printing ink, printing plates, blankets, printing equipment, and other screen printing products accessories |

Mesh Filter BagAll Macrokun mesh bags are constructed using a woven or knitted fabric. |

What is the price of screen printing machine?what is the price of a screen printing machine? I... |

6-colour 6-station double wheel rotatory screen printing machine T-shirt Heavy Duty DIYThis 6 color 6 station screen printing presses w... |

8 color octopus screen printing machine1)8 color octopus screen printing machine Applica... |

Small screen printing machine price is how much?Many people want to share their share of the scre... |

MK-F442E floor type 4 color 4 station double wheel screen printing machineIt is mainly used for the four color T-shirt over... |

-lp.jpg)