MK-S5060 three direction micro adjust vacuum screen printing machine

Description

The working principle of the vacuum table is to drive the impeller rotation by the motor of the suction pump, so as to compress and stretch the air in the pump chamber with fixed volume to form a vacuum (negative pressure). The pressure difference between the pump air inlet and the external atmospheric pressure is generated. Under the action of the pressure difference, the gas pressure (suction) is put into the pump chamber and then discharged from the exhaust port.

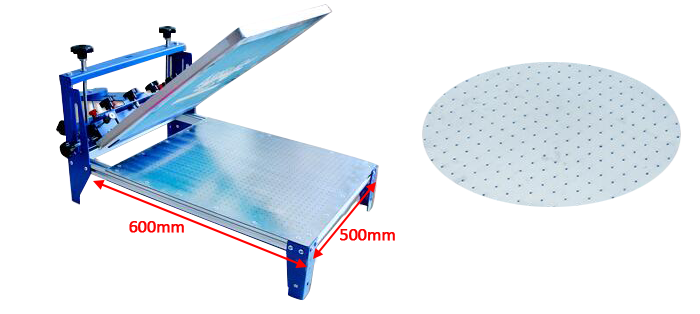

The air inlet of the vacuum screen printing machine is through hundreds to thousands of small holes on the printing surface.The substrate is placed on the suction surface by the negative pressure of the gas to form a pressure difference, so that the substrate adsorption on the surface.

| Product Code | 006156 |

| Product Name | MK-S5060 three direction micro adjust vacuum screen printing machine |

| HS Code | 8443192290 |

| Product Color | Blue |

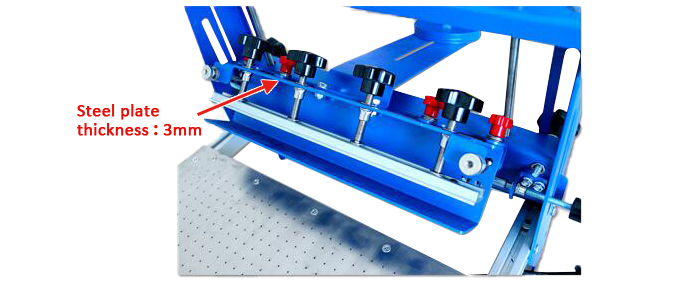

| Machine Using Material | Steel plate |

| Machine Surface Treatment | Electrostatic spraying |

| Attachment Material | Stainless steel or zinc plating, nickel plating |

| Packing Quantity | 1 |

| Net Weight | 64lb |

| Gross Weight | 75lb |

| Shelf Net Weight | 24lb |

| Packing Size | 32*22*10in |

| Packing Volume | 0.12m³ |

| Packing Material | Export fumigation-free wooden box |

Product Application

Suitable for all kinds of high precision and fine plane screen printing, especially for light and thin products, such as paper, plastic sheet, CD, credit card,PCB, as well as all kinds of film, card, board and paper. Such as all kinds of transfer printing paper, all kinds of PVC, PET, PC and other soft, hard film, all kinds of board, film, paper, nameplate, and other products. It can also be used for the fine printing of heavy and thick products, such as paper boxes, glass, wood boards, metal plates, signage, various plastic boards and other materials.

Not suitable for cloth, ribbons, handkerchiefs and other textile products.

Printing textile products are recommended to use the scraping pallet glue of the screen.

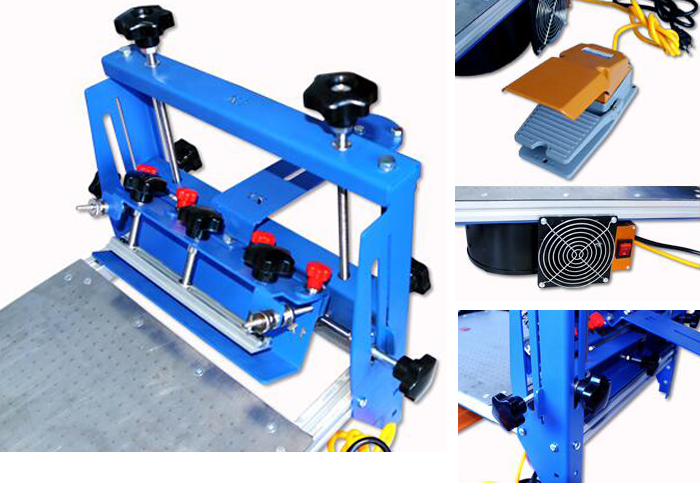

1. This screen printing table uses 2 mm stainless steel plate laser cutting, table area is 500*600 mm; Vacuum area is 526*420 mm; Suction hole diameter is 1 mm; The spacing of air holes is 15 mm. The quantity of air holes are 1044 (29 rows in horizontal direction and 36 rows in vertical direction).

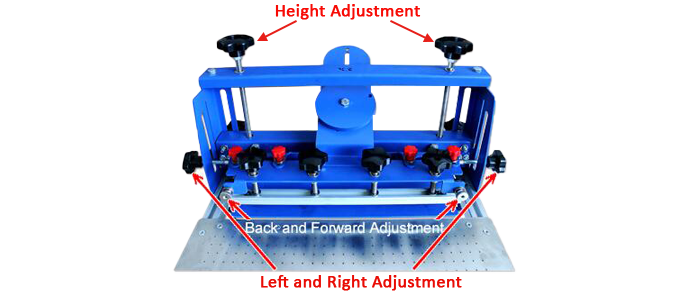

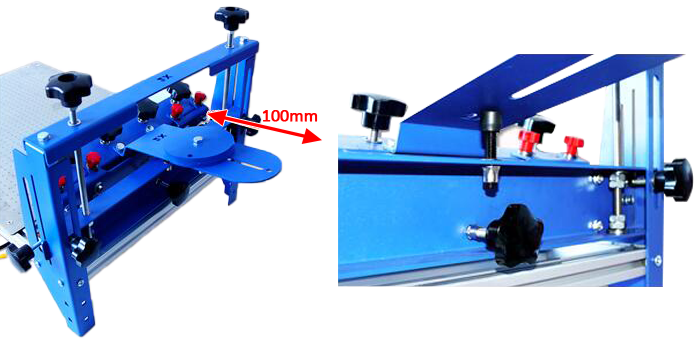

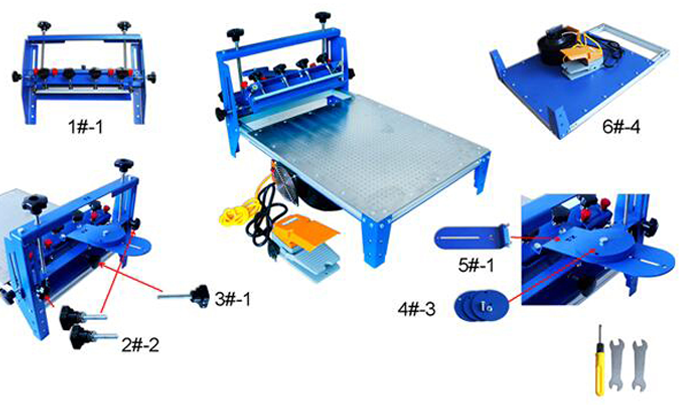

2. Fine three - directions micro adjust screen printing head;It can be micro adjusted through the knob up and down , forward and back 20 mm, left and right 20 mm ;

3. Place the substrate on the table surface and start the vacuum pump. Clamp the screen frame after aligning the screen pattern with the substrate.

4. Height adjustment: place the screen frame flat on the platform. According to the substrate height or printing requirements, rotate the up and down adjustment handle to reach the appropriate height, and lock the height through the two rear positioning handles.

5. Left and right adjustment: loosen the handle on both sides of the nose, and rotate the handle to move slightly left and right as required; When it is done,tighten both handles.

6. Back and forward adjustment: first, slightly loosen the four red knobs on the front of the chuck, then loosen the fine-tuning knobs on both sides of the front of the chuck and make front and rear fine-tuning as required.

After the fine-tuning, tighten the knob and tighten the four red knobs on the top of the chuck.

7. Screen frame chuck width is 393 mm, height is 80 mm, and it can be suitable for the use of a variety of screen frame with the thickness below 50 mm , screen frame chuck installed with four fixed handle , and the dedicated screen frame depression bar, fixed frame stress uniform, fixed frame more firmly.

8. The static balance is adjusted by gravity balance plate when the screen frame is lifted (the machine is equipped with 4 gravity balance plates, which can be installed individually or 4 installed together according to the need of balance). The gravity balance plate can move forward and backward by 100mm as required; If the frame weight is too big,heavy object can be added on the top of the balance frame gravity hole.

The lifting angle of the screen frame can be adjusted by screws in the lower part of the balance frame. The height of the screen frame after lifting can be adjusted as required.

9. When substrate area is small, adsorption will reduce, users can cover the blowholes around the substrate with plastic sheets or paper to increase the adsorption of substrate.

10. The main body of the machine adopts advanced electrostatic spraying metal surface treatment, acid and alkali resistance, corrosion resistance, cleaning resistance, no rust, long-term use; Some parts are made of stainless steel.

11. Equipped with a full set of installation tools and detailed installation instructions; Easy installation without additional tools.

How to Choose

Fast delivery, the shortest time delivery of goods

Safety First, Guaranteed and Diversified Payment

After-sales service to eliminate any concerns of customers

The product has a better price:

- We are a factory that produces screen printing. The more you buy, the cheaper your price.

- Product Number:

- Hs Code:59112000

Screen Printing Mesh6T(15 Mesh) to 165T(420 Mesh) |

Screen Printing Squeegee Bladescreen printing squeegee blades on sale at wholesale prices |

Screen Printing Squeegee Handle60 durometer , 70 durometer , 80 durometer , and 70/90/70 triple durometer. |

Screen printing Aluminum FrameScreen printing screens fulfill customers' needs and are welded for great mesh adhesion. |

Nylon Filter MeshNylon filter mesh with a wide range of mesh sizes and various types is widely used in the industries for liquid, gas and oil filtration. |

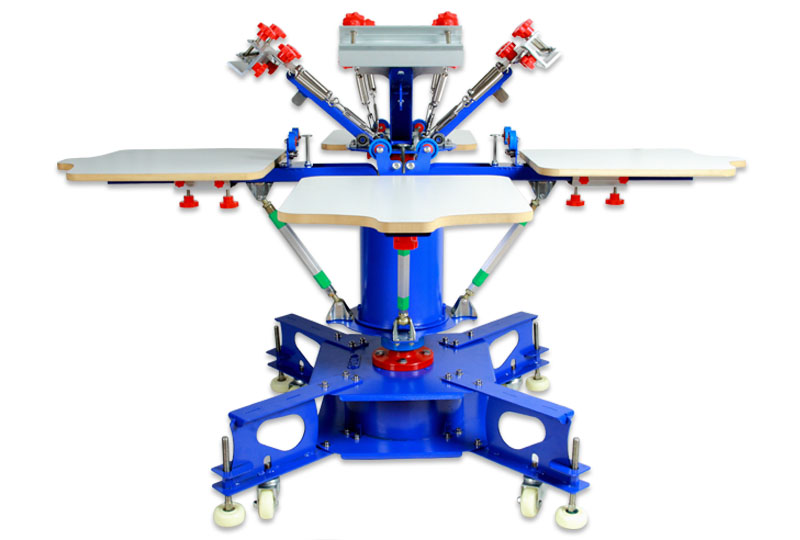

Screen Printing Machinewe have 1 color printing machine,2 color printing machine,4 color printing machine,6 color printing machine, 8 color printing machine |

Screen Printing MaterialsPrinting materials, printing equipment, printing accessories, printing ink, printing plates, blankets, printing equipment, and other screen printing products accessories |

Mesh Filter BagAll Macrokun mesh bags are constructed using a woven or knitted fabric. |

What is the price of screen printing machine?what is the price of a screen printing machine? I... |

6-colour 6-station double wheel rotatory screen printing machine T-shirt Heavy Duty DIYThis 6 color 6 station screen printing presses w... |

8 color octopus screen printing machine1)8 color octopus screen printing machine Applica... |

Small screen printing machine price is how much?Many people want to share their share of the scre... |

MK-F442E floor type 4 color 4 station double wheel screen printing machineIt is mainly used for the four color T-shirt over... |

-lp.jpg)